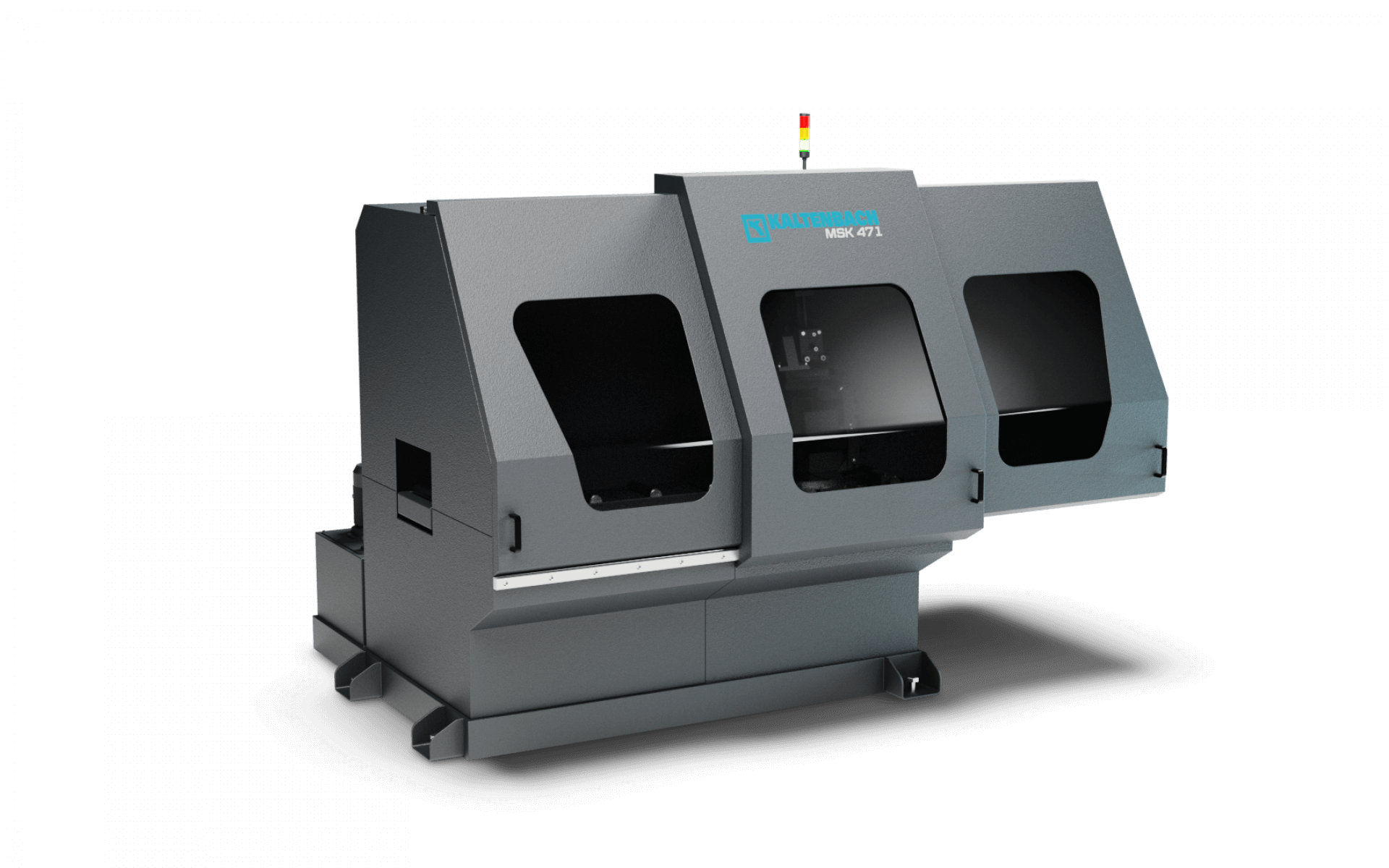

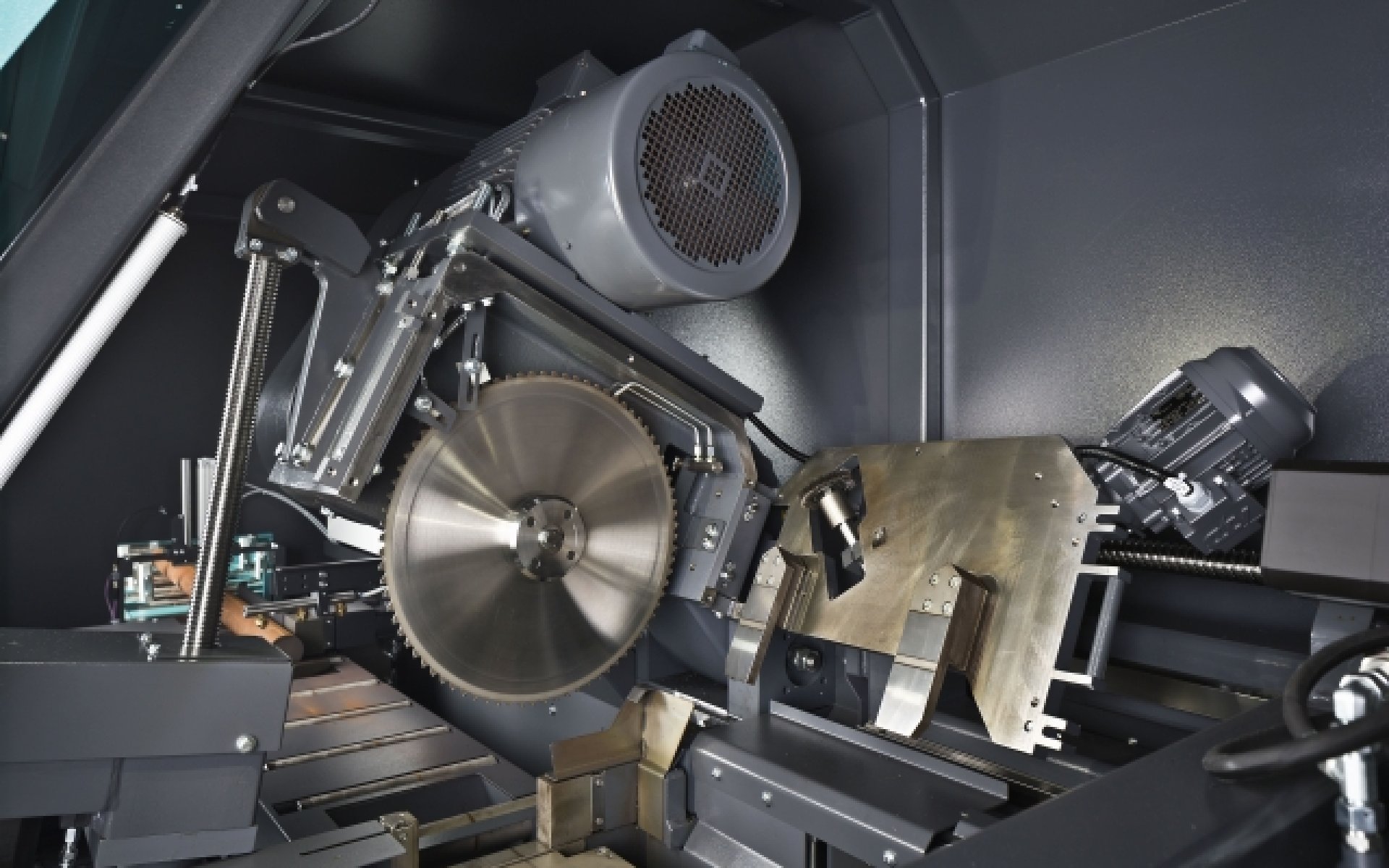

Kaltenbach MSK 471 NA Circular Sawing Machine

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

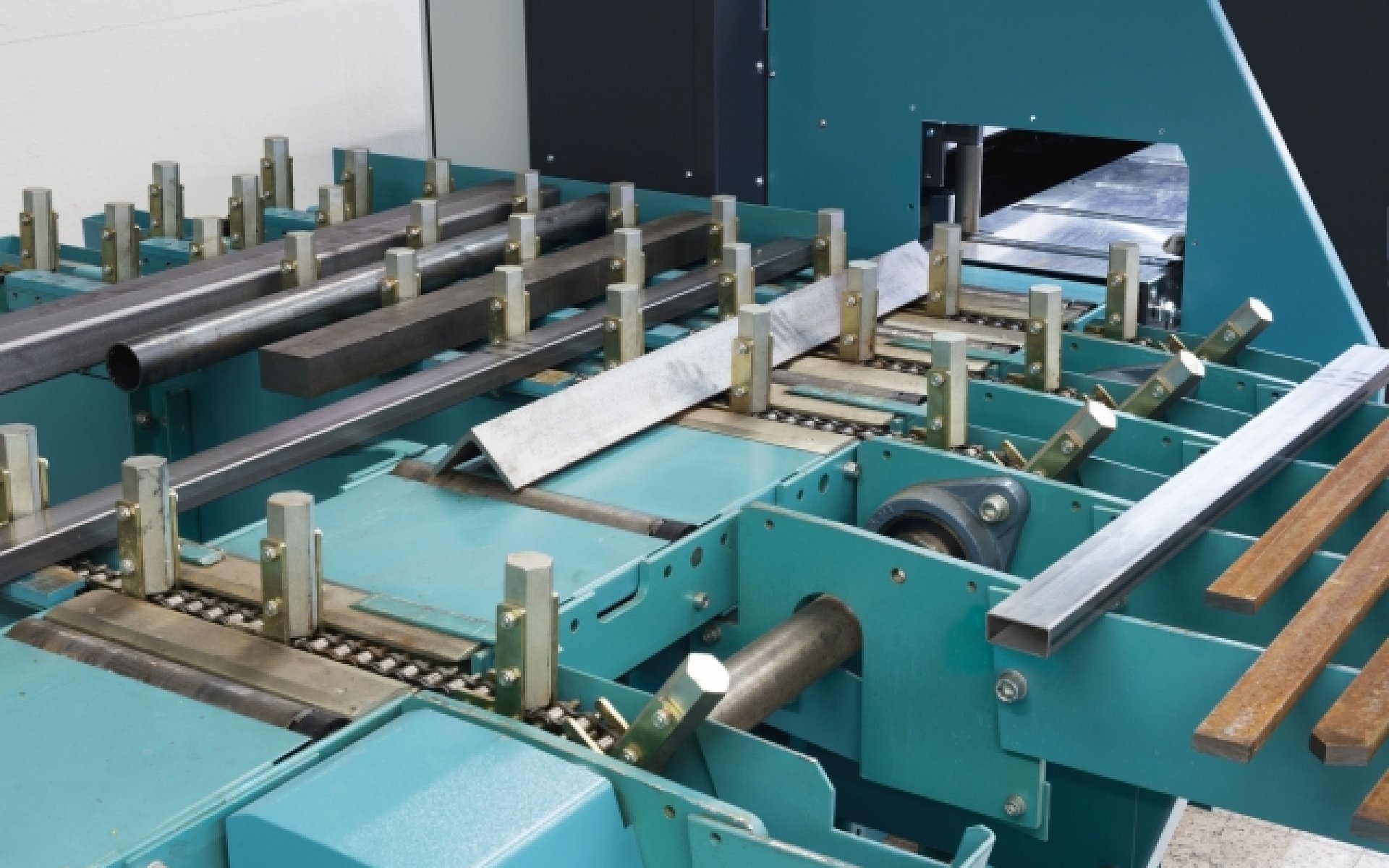

IN-/OUTFEED SIDE

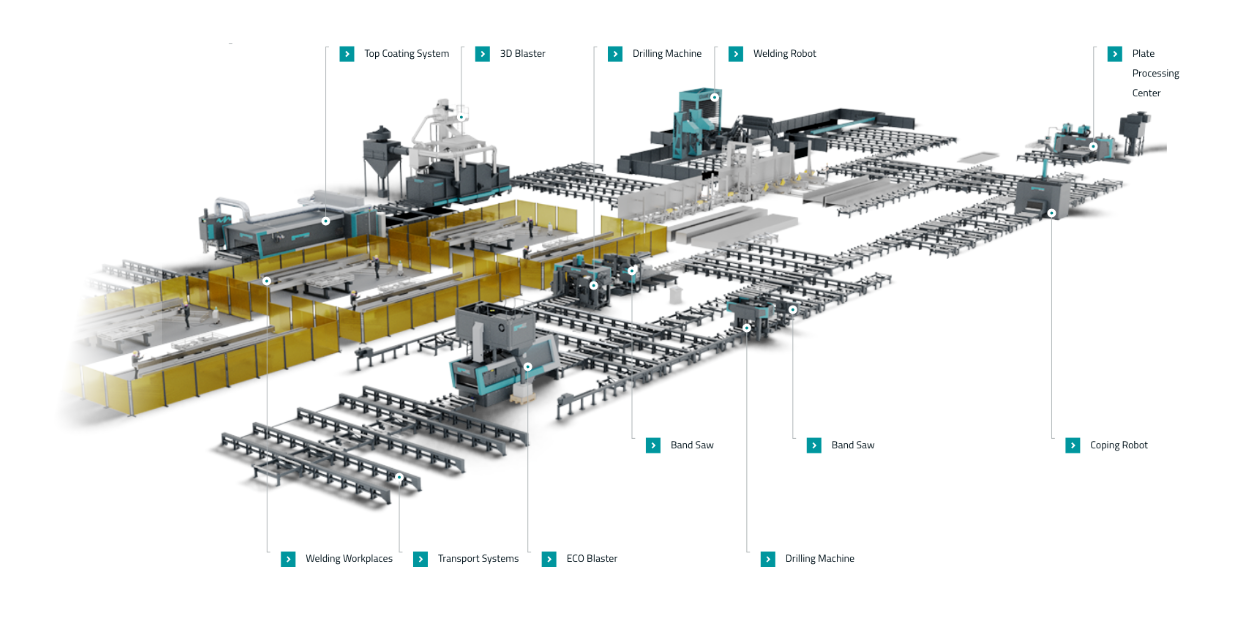

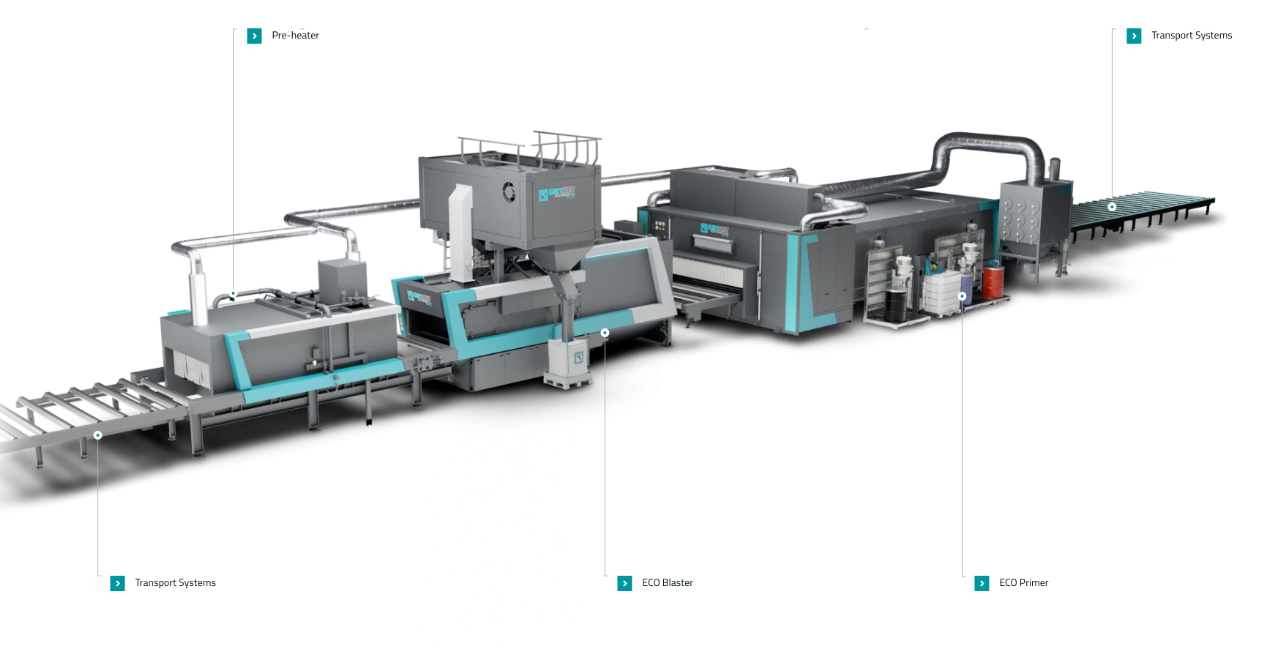

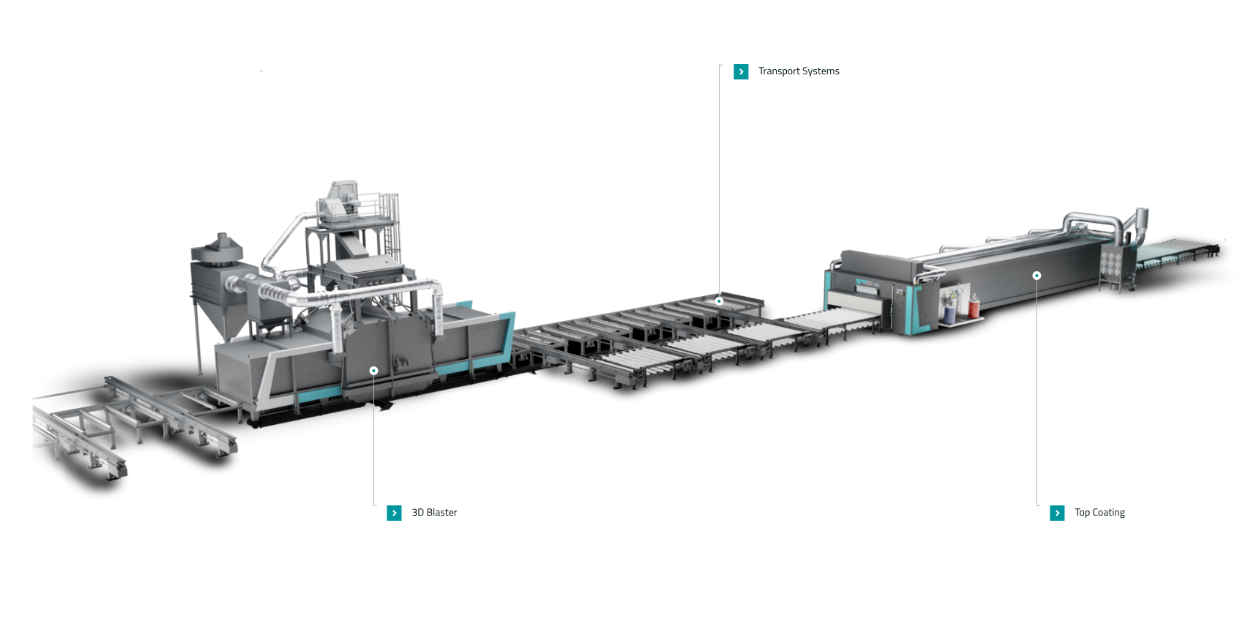

AUTOMATIC BAR SEPARATION

- VM Bundle Magazine

- For pre-storing of round and square material in the bundle

AUTOMATIC BAR INFEED

- FM 1 flat magazine

- Highly flexible universal magazine for pre-storing almost all profile shapes and solid material

- Different depths available

AUTOMATIC BAR INFEED

- LM 1 loading magazine

- For pre-storing round and square material

TILTING TABLE WITH DISTRIBUTION DEVICE

- For removal of front cuts, end pieces and cut lengths to freely-selectable positions

T 4 TRANSPORT SYSTEM FOR CIRCULAR SAWS

- For material feed and removal with circular saws

- Solid rollers running in ball bearings, optionally available with drive

- Operating width: 390 mm / Roller diameter: 60 mm

SOFTWARE

PROFICUT – EASY, USER-FRIENDLY MACHINE OPERATION

- Programming of orders via colour touchscreen with large keypads directly on the machine control console

- Storage possibility for as many sawing orders as desired

- Automatic calculation of cutting speed and feed over the material group or DIN-Nr. (steel key)

- Graphical representation of the material

- Machine operation

PROFICUT – PROFILE DATABASE

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

PROFICUT – PRODUCTION DATA REPORT

- Recording of production times of individual pieces or entire orders

PROFICUT – DATA TRANSFER AND DATA RESPONSE

- Data input directly on the machine control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

DOWNLOADS

SERVICE

HELPDESK MODULE

Whether by telephone, email or remote access, with the Helpdesk module you can take advantage of the expertise from our helpdesk team, for telephone advice and support. With remote access, we can fix (in 90% of cases) the problem quickly ensuring the highest possible system availability.

- Wide-ranging and professional fault diagnostics and solution.

- Shorter and less frequent service calls through targeted preparation.

- Individual advice and support.

MAINTENANCE MODULE

Minimize your downtime and achieve the best possible quality processing results from your KALTENBACH machine, always maintained by us with regular, expert inspection and maintenance – Always at competitive costs!

- YOU WILL NEVER NEED TO WORRY ABOUT MAINTENANCE WITH THIS MODULE.

- Minimum plant downtime.

- Transparent costs.

- Cost reduction through early fault detection and elimination.

SPARE PARTS & TOOLS MODULE

Tools, wear parts and consumables. We can give comprehensive advice on all of your needs, their technical suitability and their optimum use. By request we provide you with a monthly, quarterly or annual contract. Spare parts at competitive prices.

- WITH ORIGINAL KALTENBACH PARTS YOUR MACHINE LIVES LONGER.

- THE SPARE PARTS MODULE WILL ALSO SAVE YOU MONEY.

- Reliable and fast delivery.

- Guaranteed spare parts supply.

TRAINING & EDUCATION MODULE

Every machine is only as good as it’s operator. Regular refresher – Training and / or technology training for your operators and maintenance staff, will not only improve the productivity of your KALTENBACH machine, but also increases the professional qualifications of your employees.

- EXPERTISE AND BUILD YOUR KNOWLEDGE THROUGH THE TRAINING MODULE.

- Specially tailored to your needs and equipment.

- Increasing the life of the machine.

- Reducing errors, downtime and setup times.

- Ensuring consistent processing and product quality.

- Ensuring Factory Settings are maintained by highly trained maintenance personnel.

SUPERIOR MACHINERY SERVICES

During these trying times and to cope up with the global demands for 24x7 and superb after-sales service, SMS is proud to offer our very own Superior Machinery Services to address any technical concerns to help maximise the performance of your machinery. Please see click below our services brochure for more information:

Superior Machinery Services (Brochure)

Introducing remote diagnostic support via augmented reality helmet

SMS provides remote support with augmented reality helmets to maintain your fleet of machines at full capacity and quality. This rechargeable helmet serves as the customer's eyes and ears, allowing our service technician to assist you with installation and repair. The smart helmet is available for hire for $250 per hour.

SMS understands the importance of keeping your fleet of machinery running. The services brochure include information on what levels of support we can provide including the schedule of fees and scope of services. Contact us for more information.

Request a machinery evaluation

WHY BUY?

Click the testimonials and case studies to see the positive gains your peers are gaining:

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

KALTENBACH MSK 471 NA CIRCULAR SAWING MACHINE

fully-automatic universal saw for straight cutting, workspace [mm]: 152

Fully-automatic universal saw for straight cutting, designed for the optional use of HSS and carbide tipped saw blades and features especially short length of remnant workpieces.

BENEFITS AT A GLANCE

-

- Fully-automatic processing and sorting of finished pieces

- Low vibration due to the extreme stiffness of the components

- Minimal end-piece lengths

- High productivity with good saw blade life

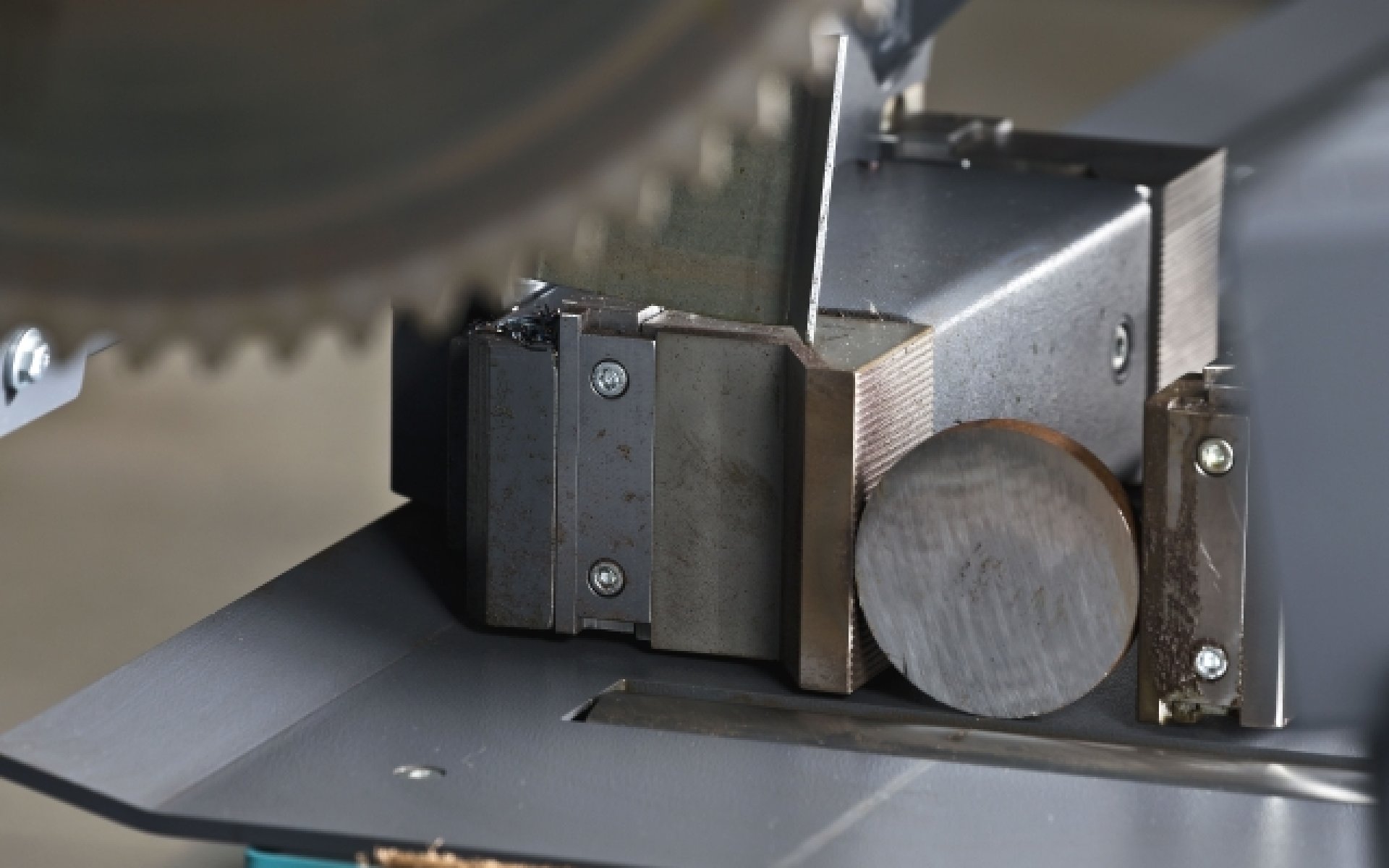

- Material feed gripper

- Sawblade feed with static ballscrew spindle

- Combined drive for HSS and carbide-equipped tools

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from a Kaltenbach MSK 471 NA Circular Sawing Machine. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to deliver to your business and your clients successfully.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share the business challenges and solutions that you have encountered and how steel processing automation has helped achieve your business objectives.

JOIN HERE >>>