Haeusler CRWM Tack Welding Machine Assembly Equipment

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

- Haeusler Pipe Mill - Brochure

- Haeusler Wind Mill - Brochure

- Haeusler Company Profile – Brochure

- Haeusler Global Service

- Haeusler Remote Services Support

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

SERVICE

Production must be reliable and precise so that products can be manufactured with consistently high quality. The potential for increasing productivity must be identified and used to remain competitive.

HAEUSLER Global Service supports you in all matters, from the initial machine setup to production optimisation and ordering spare parts. For plants to be modernised, for which the spare parts supply is no longer guaranteed, you will receive a binding offer including all necessary parts, the modification work on-site as well as commissioning.

Prompt service from our highly qualified engineers is possible at any time by remote access to the production plant, augmented reality or by telephone.

With HAEUSLER Global Service in good hands, reliable and worldwide.

REMOTE SUPPORT SERVICES

Through the use of modern communication technologies such as remote maintenance systems and augmented reality, we are able to carry out immediate error detection, diagnosis, maintenance, data analysis or optimisation without sending a technician.

WHY BUY?

Click the testimonials and case studies to see the positive gains your peers are gaining:

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

NEWS

- The wind tower industry is growing

- Versatile, flexible, affordable in operation - introducing the EVO 4-roll bending machine

- Haeusler AG celebrates its 85th anniversary

- Introducing Haeusler BENDtronic - Efficiency by simplicity

- SeAH Steel Corp., one of the world's largest manufacturers of onshore and offshore wind towers chooses Haeusler for their facility in the UK

- Haeusler Solutions for Offshore Wind Tower Manufacturing

- Haeusler introduces AR-Remote Support

- Haeusler - Your partner for bending

- Haeusler Newsletter // June 2021

- Haeusler Newsletter // July 2021

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

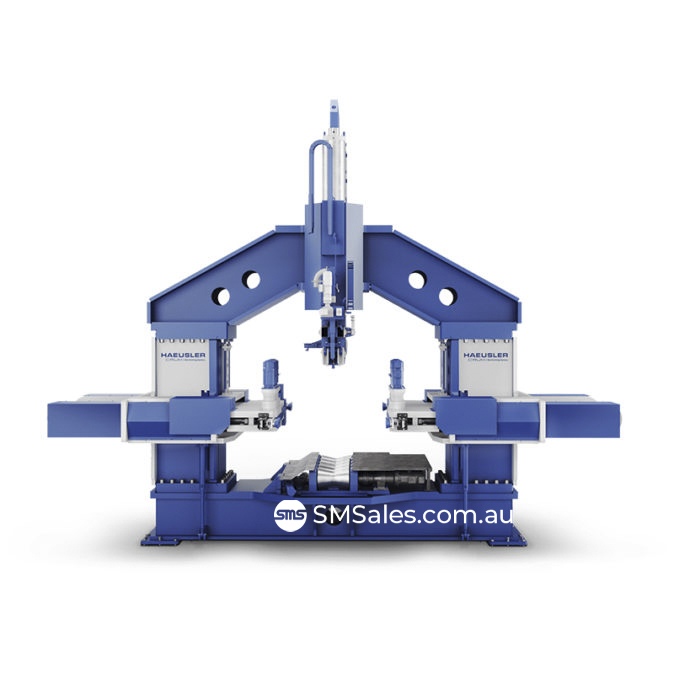

Haeusler CRWM Tack Welding Machine Assembly Equipment

Perfectly Welded Pipes from Start to Finish

The HAEUSLER CRWM is used both in HAEUSLER pipe manufacturing plants and in other pipe mills around the world.

The accuracy of the edge alignment and continuity of the weld bead of the tack welding process is the basis for all subsequent submerged arc welding processes and thus the key factor for pipe quality. The latest generation of HAEUSLER tack welding machines ensures a new level of pipe quality through active pipe manipulation during the welding process (spinning control).

This patented system in combination with the high-low rollers installed on the machine, which guarantee a perfect weld seam from the beginning to the end of the tube, and the CNC-controlled laser tracking with digital welding equipment, offers absolute production flexibility and secure, stable production.

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from a Haeusler CRWM Assembly Equipment. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to successfully deliver to your business and your clients.

join our LinkedIn group

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share your business challenges and solutions that you have encountered and how steel processing automation had helped achieved your business objectives.

Join here >>>

.png)

.png)