Haeusler EVO 4 Roll Plate Bending Machine - New Technology

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

CONTROLS

SINGLE RADIUS MULTI PASS

Automatically generates CNC programs to achieve a complete cylindrical workpiece even when multi-pass bending is required.

MULTI-RADII CALCULATOR

Automatically generates a full CNC program to achieve the desired multi radii workpiece even for multi-pass bending applications.

APPLE CALCULATOR

Calculates the different possibilities to achieve the usually desired “apple shape” of a cylindrical piece when prebending.

BEND CALCULATOR

Calculates the required positions of the rolls to achieve the desired radius.

CAPACITY CALCULATOR

Shows if the desired workpiece can be bent. Additionally, the tool shows the load applied on the machine as well as the remaining flat ends and spring back that can be expected.

COST REDUCTION

HHDS – HAEUSLER HYBRID DRIVE SYSTEM

HIGHEST EFFICIENCY COMBINED WITH SUPERIOR PRODUCTIVITY

The HAEUSLER Hybrid Drive System HHDS® provides an unmatched efficiency due to the consequent usage of electrical motors in combination with planetary gearboxes. In practice, this means savings of up to 50% of the running costs. Additionally, the Hybrid Drive System allows a step-less adjustable rotation speed from 0 – 8 m/min. This is, compared to other machines that are available on the market, an increase of 60% and the basis for high productivity.

WORKING SPEED IN COMPARISON

TECHNOLOGY

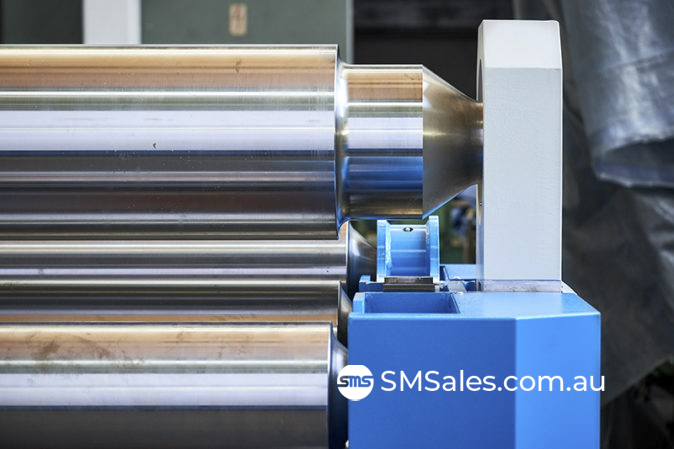

VSA TECHNOLOGY ALLOWS BENDING OF THICKER PLATES AND SMALLER DIAMETERS

The new and patent-pending VSA® – technology allows the operator to bend either very heavy wall thicknesses or alternatively very small diameters. This can be realized by a unique adjustment of the bending geometry. The EVO is worldwide the only 4-roll plate bender with this unique feature. For our clients, it means that they are now in a position to get a machine with up to 85% more bending moment compared to conventional bending machines. Additionally, they get the possibility to use super small interchangeable top rolls for bending tight diameters.

HAEUSLER VSA – SHIFTING UP THE LIMITS

By using two instead of only one pivot point for each side roll swing arm fixation, the machine can individually be adjusted either to create a wide bending geometry for heavy wall thicknesses or a tight geometry if small diameters shall be bent. The above shown graphic displays the increase in bending moment that can be achieved by this new technology compared to a conventional 4-Roll Plate Bending Machine.

SERVICE

Production must be reliable and precise so that products can be manufactured with consistently high quality. The potential for increasing productivity must be identified and used to remain competitive.

HAEUSLER Global Service supports you in all matters, from the initial machine setup to production optimisation and ordering spare parts. For plants to be modernised, for which the spare parts supply is no longer guaranteed, you will receive a binding offer including all necessary parts, the modification work on-site as well as commissioning.

Prompt service from our highly qualified engineers is possible at any time by remote access to the production plant, augmented reality or by telephone.

With HAEUSLER Global Service in good hands, reliable and worldwide.

REMOTE SUPPORT SERVICES

Through the use of modern communication technologies such as remote maintenance systems and augmented reality, we are able to carry out immediate error detection, diagnosis, maintenance, data analysis or optimisation without sending a technician.

WHY BUY?

Click the testimonials and case studies to see the positive gains your peers are gaining:

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Machine Demo

Request Software Demo

Request Layout

Request Quote

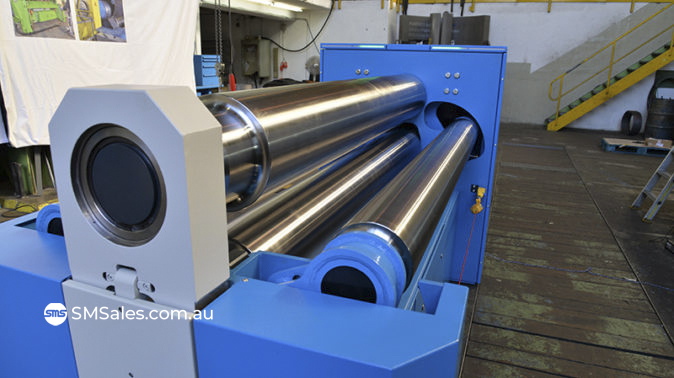

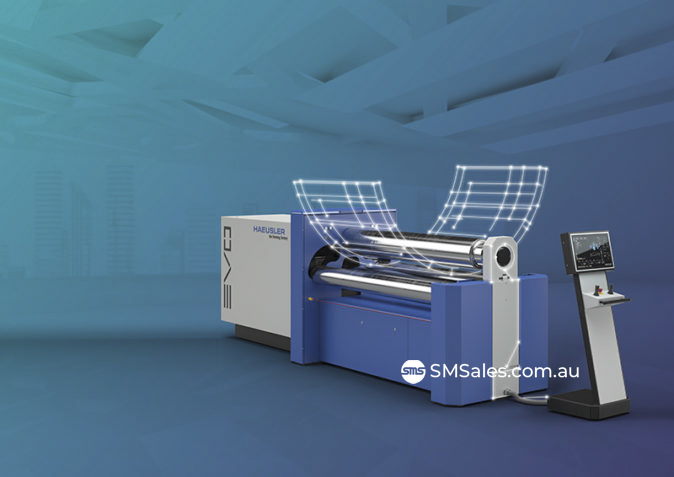

HAEUSLER EVO PLATE BENDING MACHINE

The future of bending begins now

Reduced running costs, increase in productivity and super easy to use: EVO comes with a bunch of outstanding benefits. Of course, in premium HAEUSLER quality – made in Switzerland.

All EVO machines are already extremely well equipped as standard. Even in their basic configuration, they are far superior to all other machines on the market. To meet special customer requirements, we offer optional accessories, which can be added either directly to the machine or later at any time.

Explore an array of videos by clicking on WATCH THE VIDEOS above.

We will provide auditable, deliverable, measurable, and evidence-based metrics for your strategic team to calculate the ROI, capacity increase, and man-hours reduction achieved with a PCR42 Plasma Coping Robot. SMS will assess your current position, ongoing strategy, and any gaps to ensure successful delivery to your business and clients.

.jpg)

.jpg)

.jpg)

.jpg)