SLF Media Blast Robot ReCo-Blaster - Blasting Systems

Some paragraph content...

WATCH THE VIDEOS

SLF BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS FOR THE STEEL CONSTRUCTION SECTOR

SLF BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS FOR THE MACHINE CONSTRUCTION SECTOR

SLF BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS FOR UTILITY VEHICLES

SLF BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS FOR THE RAIL VEHICLE SECTOR

DATA SHEETS & BROCHURES

- SLF Media Blast Robot ReCo-Blaster® – Brochure

- SLF Blasting and Paint Spraying Systems for Wheeled and Tracked Vehicles -Brochure

- Surface Treatment Centre – Petricio – Data Sheet

- Surface Treatment Centre – Siemens Wien – Data Sheet

- Open-space Paint Spraying System with Telescopic Dryer & Blast Room – Codeme – Data Sheet

- Blastrooms, Combined Paint Spraying & Drying Booths & Open-space Paint Spraying System – SIAG – Data Sheet

- Blastrooms & Open-space Paint Spraying Systems – Steelwind – Data Sheet

- Blastroom & Open-space Paint Spraying Systems with Telescopic Drying Tunnel – ZSK – Data Sheet

- Blastroom & Open-space Paint Spraying System with Telescopic Dryer – JÖST – Data Sheet

- Blastroom & Open-space Paint Spraying System with Movable Telescopic Dryer – Schone & Bruns – Data Sheet

- Blastroom with Longitudinal & Cross Lamella-type Conveyor & Extraction System for Zinc Spraying – Calder Steward (NZ) – Data Sheet

- SLF Product Catalogue

- SLF Customer Magazine

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

WHY BUY?

slf - BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS AT CODEME

who are slf - BLAST SYSTEMS, PAINTING INSTALLATIONS & CONVEYOR SYSTEMS

SPECIALIST MACHINERY SALES - SUPPLYING SUPERIOR MACHINERY STRATEGIES TO AUSTRALIA AND NEW ZEALAND

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

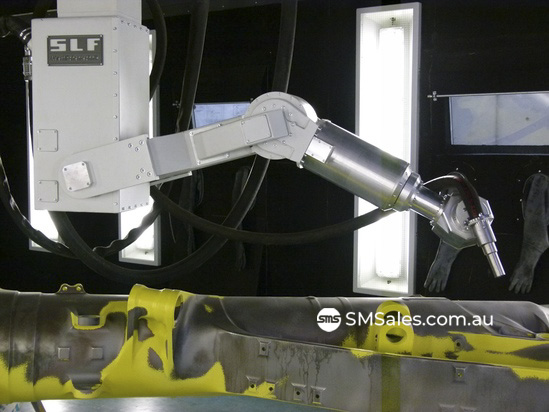

SLF MEDIA BLAST ROBOT RECO-BLASTER® – BLASTING SYSTEMS

BLASTING LARGE SERIAL PARTS AUTOMATICALLY BY MEANS OF MEDIA BLAST ROBOT

In order to achieve a more efficient and economical blasting of workpieces, particularly of large serial parts, we have developed the media blast robot “ReCo-Blaster®“, which in the meantime has well proven for different applications.

The Media Blast Robot “ReCo-Blaster®“ is Practice Approved

Our previous applications include the automated blasting of landing gears of air carriers, components for the wind energy sector or large serial parts for the conventional steel construction sector or the foundry industry.

Take the Opportunity to Optimise your Process for the Blasting of Large Serial Parts

Under certain conditions, the media blast robot can be integrated into your existing blastroom.

Switch to automated blasting now!

Advantages of the Media Blast Robot

-

- Multiply increased surface treatment rate by larger blast nozzle diameter and higher blasting pressure

- Consistent blasting quality and reproducible results by monitoring of all blasting parameters

- Very high working and process reliability

- Suitable for all types of blast media

- Continuous blasting process

Control Options

-

- Offline programming

- Handheld operating panel

- The air-conditioned and soundproofed operator cabin

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from an SLF Media Blast Robot ReCo-Blaster® Blasting System. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to successfully deliver to your business and your clients.

Photos source: SLF Oberflächentechnik GmbH.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share your business challenges and solutions that you have encountered and how steel processing automation had helped achieved your business objectives.

JOIN HERE >>>