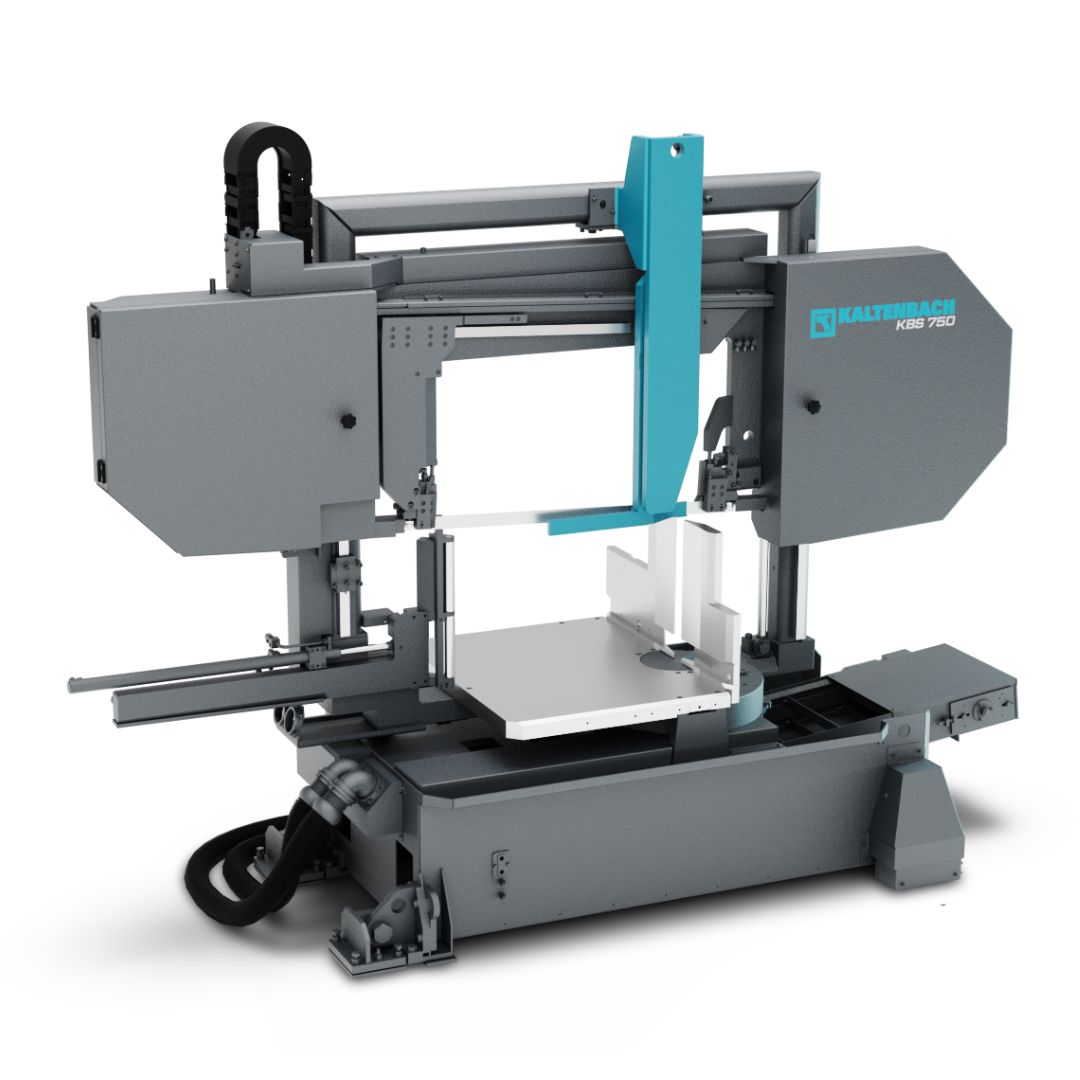

Kaltenbach KBS 621 Bandsaw Machine

Some paragraph content...

- WATCH THE VIDEOS

- BROCHURES

- FEATURES

- SOFTWARE

- COMPLEMENTARY

- ALTERNATIVE MACHINES

- SERVICE

- WHY BUY?

- HOW TO BUY?

WATCH THE VIDEOS

BROCHURES

- Superior Machinery Systems- Integrated High-Quality Solutions for the Steel Industry

- Superior Machinery Systems- High Performance Steel Processing Systems

- Superior Machinery Systems- Semi-automatic Universal Sawing Machines

- Superior Machinery Systems- Fully Automatic Universal Sawing Machines

- References for Steel Processing Projects

- References for Shot Blasting and Painting Projects

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

FEATURES

HYDRAULIC FEED CONTROL WITH MONITORING

- Powerful feed

- Fast and easy feed adjustment even during runtime

NC-CONTROLLED ANGLE SETTING

- Precise angle setting for high quality cuts

- NC-standard enables highest reliability

HORIZONTAL AND VERTICAL CLAMPING DEVICE

- Clamping directly next to operation area

- Low vibrations for long saw band lifetime and low operating costs

- Cutting of material layers and bundles possible

SWITCHING FROM RAPID TO PRE-SET FEED RATE

- Automatic switching from rapid feed approach to pre-set feed rate

- Low idle times and higher machine utilization

- Feature is fully independent from machine program

AUTOMATIC HYDRAULIC CUTTING PRESSURE CONTROL

- Automatic feed control based on band pressure detection

- Extended saw band life time based on material and band status

HYDRAULIC BAND TENSION

- Set the right tension level for a cutting process

- High tension is activated during cutting process

- Low tension during idle time for long band lifetime

MINIMUM QUANTITY LUBRICATION

- MQL ensure longer saw band lifetime

- No lubrications rest on the material possible

CHIP REMOVAL BRUSH

- Less contamination of the machine and its environment

- Higher cutting performance

- Less wear on saw band for longer lifetime and lower costs

ELECTRONIC BAND SLIP MONITOR

- Rotation speed measurement of both saw wheels

- Slippage is reliable detected

- Cutting process is stopped automatically

POWERFUL DRIVES

- Fast and powerful cuts for single beams as well as material layers or bundles

- Shortest processing times for high tonnages

ROBUST SAW IN SOLID TWIN PILLAR CONSTRUCTION

- High cutting performance and precision

- Long lasting construction for long investment cycles

- Inclined saw band for higher average feed rates

CHIP CONVEYOR

- Automated chip handling

- Higher comfort for operator

OFFICE SOFTWARE LICENSE

- Parts can be programmed, imported and nested in the office

- Real-time feedback of production status

BAND DEFLECTION MONITOR

- Automatic detection of band deflection

- Sensor results will be shown to the operator

- Maintenance can be executed according to real machine conditions

LASER LINE PROJECTION

- Laser projection for manual cuts

- Transport system control directly on machine portal

AUTOMATIC HYDRAULIC LOWERING

- Lowering of machine base reduces collision risk when new material comes in

- Less wear on clamping unit and cutting table

SOFTWARE

PROFICUT – EASY, USER FRIENDLY MACHINE OPERATION

- Programming of orders via color touchscreen with large keypads directly on the machine control console

- Storage possibility for as many sawing orders as desired

- Automatic calculation of cutting speed and feed over the material group or DIN-Nr. (steel key)

- Graphical representation of the material

- Machine operation

PROFICUT – PROFILE DATABASE

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

PROFICUT – PRODUCTION DATA REPORT

- Recording of production times of individual pieces or entire orders

PROFICUT – DATA TRANSFER AND DATA RESPONSE

- Data input directly on the machine control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

DOWNLOADS

COMPLEMENTARY

.jpg?width=280&height=190&name=superior-machinery-systems-drill-line-light-medium-heavy-duty-steel-fabrication-service-centres%20(1).jpg)

KDM 615 PROFILE DRILLING MACHINE

- Drilling machine for drilling, tapping, countersinking, marking and milling

- Powerful motors for high performance applications

- Processing on up to 3 axis simultainelsly

- Automatic tool change with up to 5 tools per axis

- Integrated material measurement system for high precision

ALTERNATIVE MACHINES

KBP 1001 BAND SAWING MACHINE

Highest cutting performance and best cutting results. Designed for a high level of automation and low maintenance requirements. The robust and low-vibration twin-column construction ensures a long machinery life. KALTENBACH Band saw Performance. Perfect successor of successful KBS 761 | 1051 | 1351 series. The fastest band saws in the world.

SERVICE

OPTIMAL AVAILABILITY AND PERFORMANCE

With over 135 years in business, we are the experts in steel processing and surface treatment. Our custom made service solutions guarantee that you benefit from an optimal performance, availability and continuous high quality output of your investment.

Excellent Preventive Maintenance Packages

Maximum uptime can be ensured thanks to our excellent preventive maintenance packages. Together with you, our skilled engineers will keep your equipment up to date, improve your process efficiency and give advice to meet new market demands.

Advanced Process Monitoring Systems

With the help of advanced process monitoring systems, you will get a clear insight in your machine performance, and preventive maintenance can be planned in time.

Professional Helpdesk

For fast and immediate assistance, you can rely on our help desk. Spare parts and assistance will be quickly on site, whenever and wherever needed.

Original Spare Parts and Starter Kits

Original spare parts stand for optimum efficiency, higher uptime and a longer service life of your machine. In order to safeguard production continuity and short down time, you can make use of various starter kits. In that case you will have all parts you need on stock.

First Class Assistance On Site

Knowledge, experience and a passionate commitment to support our customers in the best possible way is what makes our service strong. Together, we will look for the best manufacturing methods for your products.

Effective Training

Tailor-made training programs will improve the productivity of your machine, as well as the skills of your employees.

WHY BUY?

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

KALTENBACH KBS 621 DG BANDSAW MACHINE

MITRING BAND SAW FOR LIGHT- AND MEDIUM-DUTY STEEL FABRICATION AND SERVICE CENTRES

WORKSPACE 90° [MM]: 620 X 500

BENEFITS AT A GLANCE

-

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting-edge visualisation for manual cuts

Explore an array of videos by clicking on WATCH THE VIDEOS above.

Unlock your potential with this superior Kaltenbach KBS 621 Bandsaw Machine. Specialist Machinery Sales is committed to delivering tangible results, providing auditable, deliverable, measurable, and evidence-based metrics for your strategic team to calculate ROI, capacity increase, and man-hours reduction. Our comprehensive assessment includes evaluating your current position, ongoing strategy, and identifying any gaps to ensure successful delivery to your business and clients. Trust Specialist Machinery Sales to optimise your operations and drive success with the innovative Kaltenbach KBS 621 Bandsaw Machine.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)