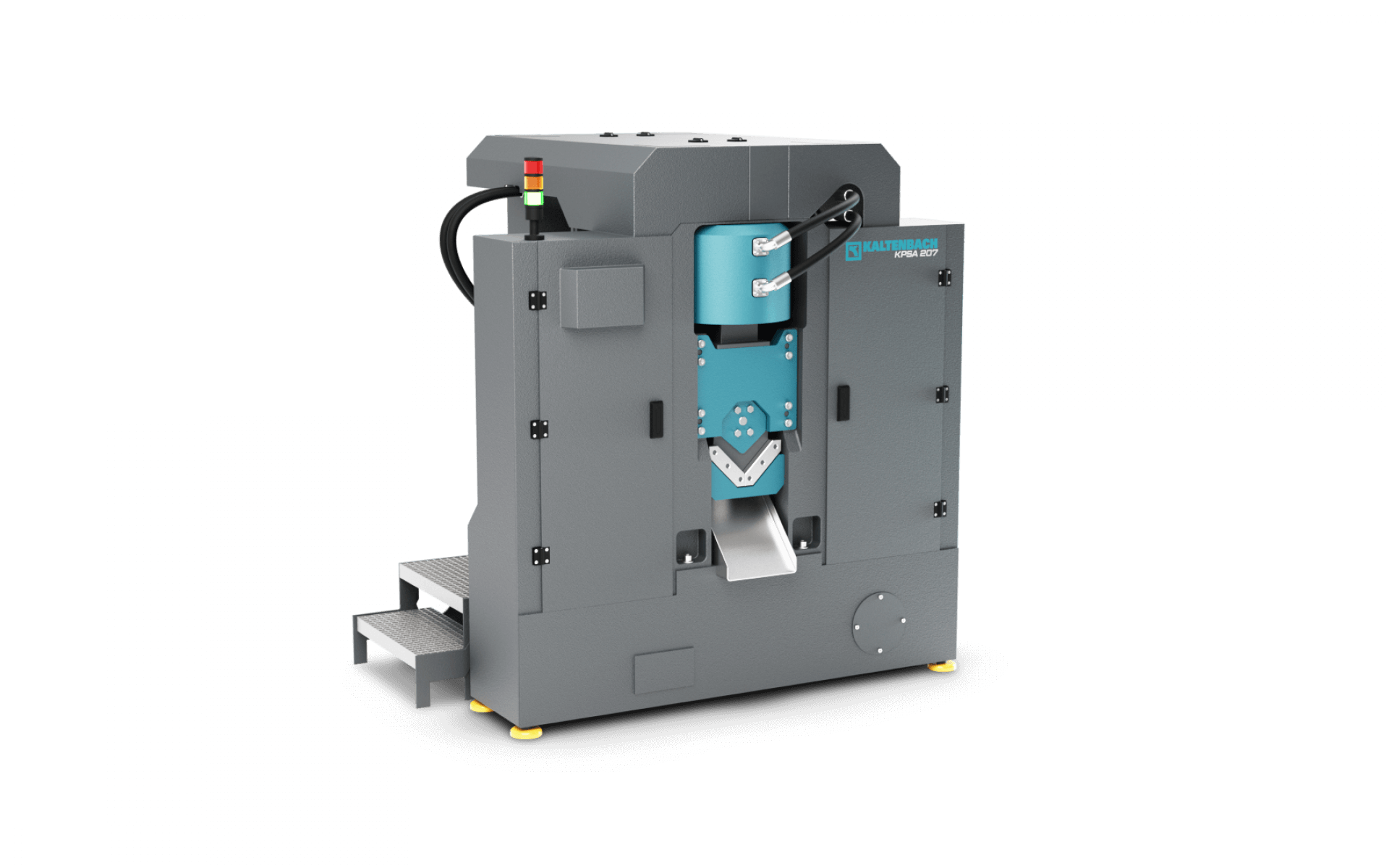

Kaltenbach KPSA 207 Punching & Shearing Machine

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

FEATURES

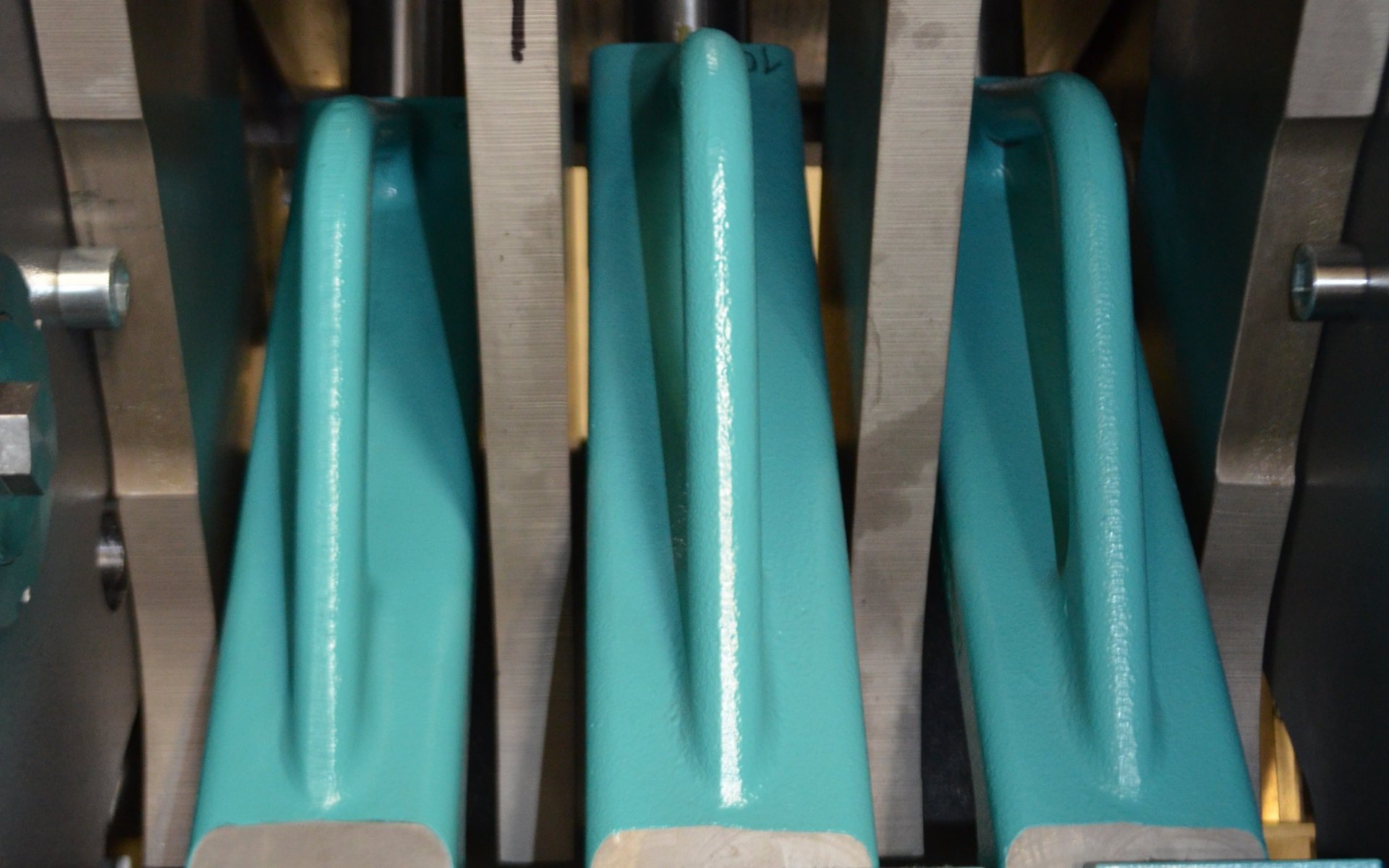

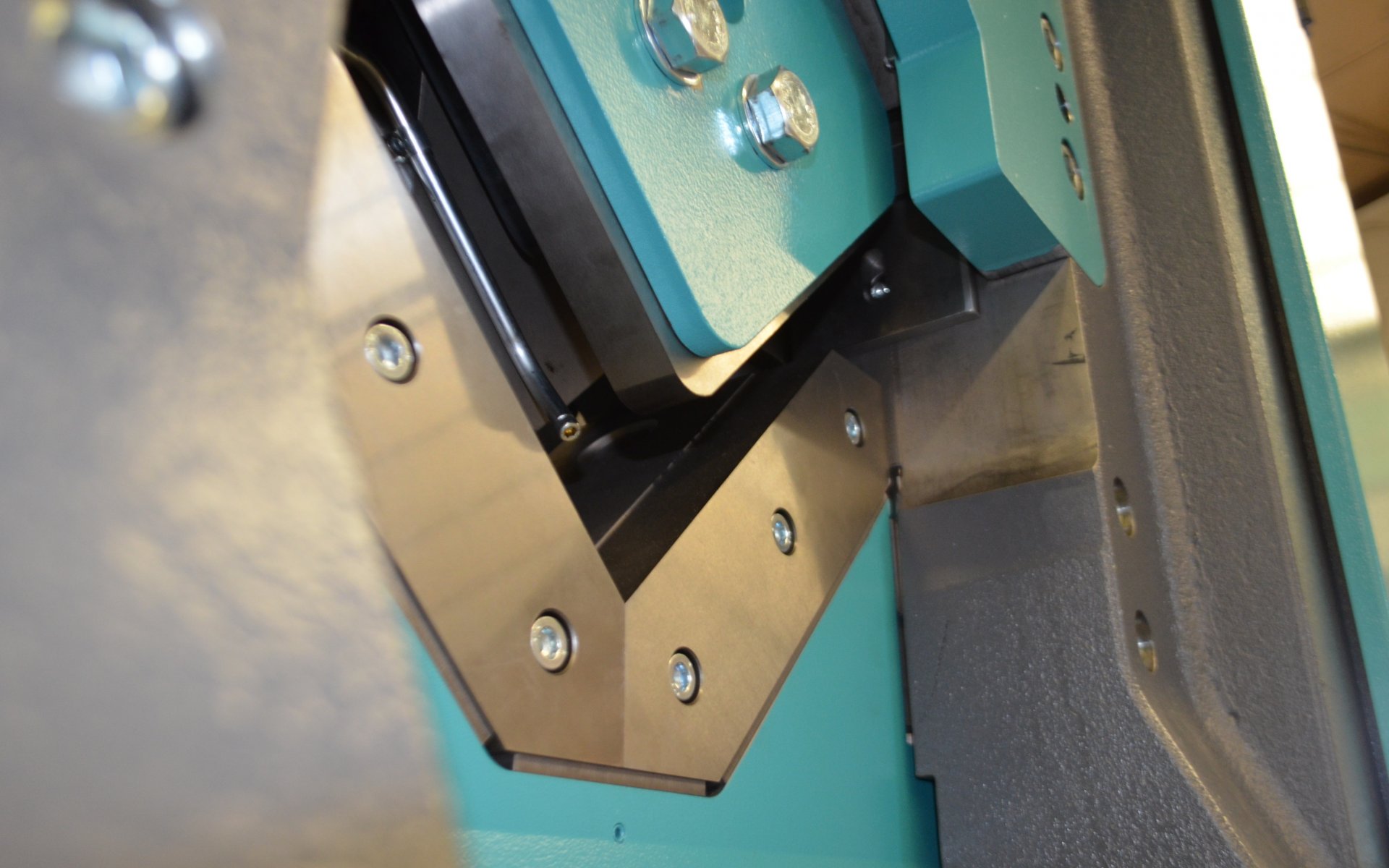

FLANGE-PUNCHING UNIT: HIGH FLEXIBILITY

- High quality punching and long tool life

HIGH FLEXIBILITY IN PRODUCTION

- Double-cut shearing unit: No deformation of the cut pieces

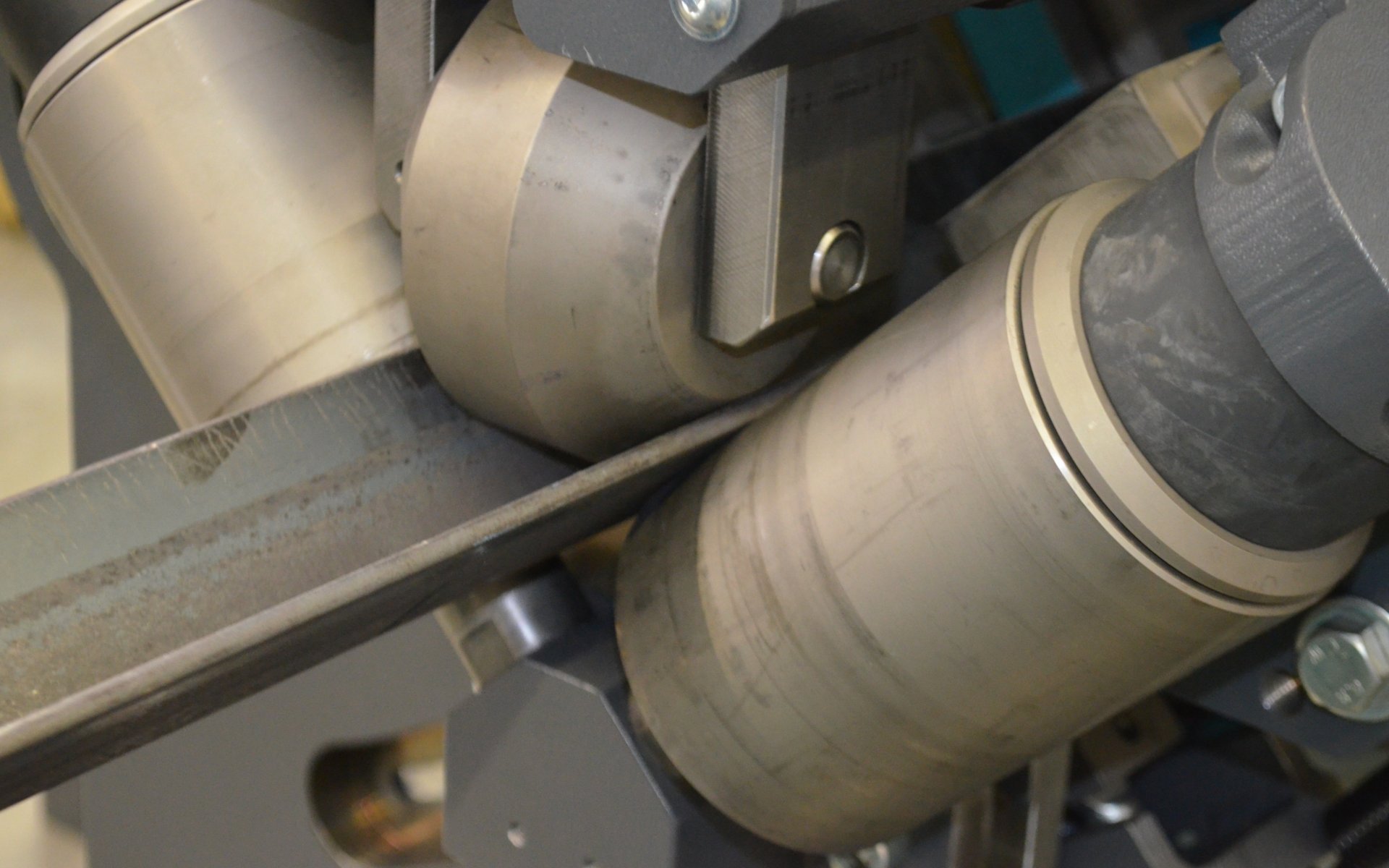

MARKING UNIT WITH TRIPLE MARKING WHEEL FOR ANGLE STEEL

- Each character can be exchanged separately

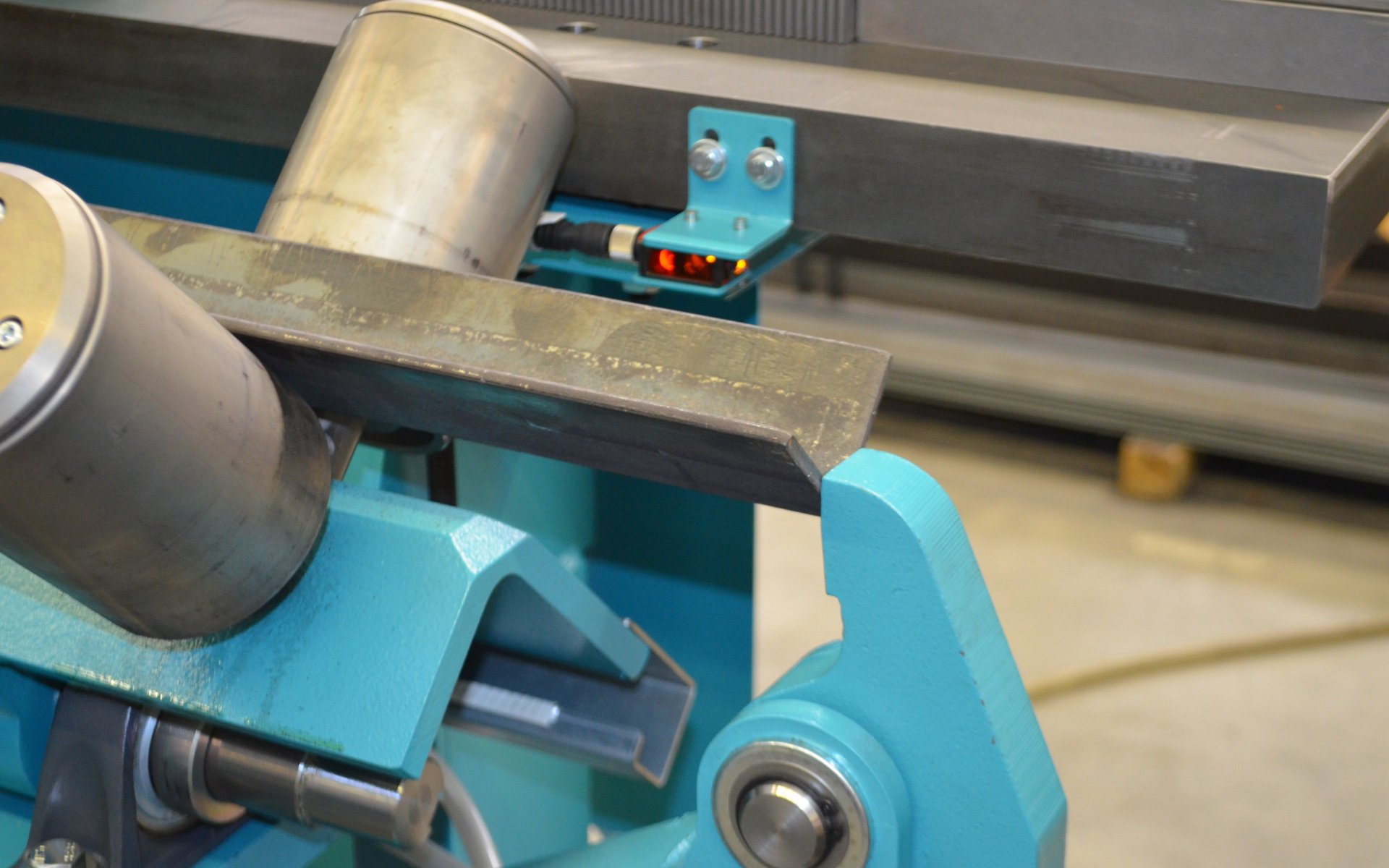

AUTOMATIC MATERIAL THICKNESS MEASURING

- Error prevention during operation process

COMPLEMENTARY

FAST MATERIAL CROSS TRANSPORT

- Load-bearing conveyor chains enable the easy, low-noise transport of materials

- Ensured supply of materials for optimal process flow

STANDARD EQUIPMENT FOR PUNCHING- AND SHEARING SYSTEMS

- Running on backlash-free linear bearings, with servo-regulated positioning drive with rotary encoder and planetary gearing via rack and pinion

- High positioning accuracy

STANDARD EQUIPMENT FOR PUNCH-SHEAR MACHINES

- Material is moved to a stop and clamped with a gripper

- Accurate measuring of material

- Secure gripping of material

STANDARD EQUIPMENT OF PUNCH-SHEAR MACHINES

- Secure transport of material

OPTIONAL EQUIPMENT LENGTH MEASURING SYSTEM

- Good piece/rest bar separator for long parts

OPTIONAL EQUIPMENT TRANSPORT SYSTEM

- Good piece/scrap separator for short parts

SOFTWARE

MULTILINE – EASY, USER FRIENDLY MACHINE OPERATION

- Programming of orders via colour touchscreen with large keypads directly on the machine control console

MULTILINE – ORDER MANAGER

- Create, copy and delete orders

- Graphic display of individual positions within an order

MULTILINE – PROFILE DATABASE

- Comprehensive profile database

- Easily expandable

- Graphic display of workpiece forms

MULTILINE – TOOL MANAGER

- Tool Changer setup based on the tool type and diameter

MULTILINE – PRODUCTION DATA REPORT

- Recording of production times of individual pieces or entire orders

MULTILINE – DATA TRANSFER AND DATA RESPONSE

- Data input directly on the machine control console

- Data import in DSTV or DSTV+ format

- Data export of previously produced parts in DSTV feedback format to any directory

DOWNLOADS

SERVICE

HELPDESK MODULE

Whether by telephone, email or remote access, with the Helpdesk module you can take advantage of the expertise from our helpdesk team, for telephone advice and support. With remote access, we can fix (in 90% of cases) the problem quickly ensuring the highest possible system availability.

- Wide-ranging and professional fault diagnostics and solution.

- Shorter and less frequent service calls through targeted preparation.

- Individual advice and support.

MAINTENANCE MODULE

Minimize your downtime and achieve the best possible quality processing results from your KALTENBACH machine, always maintained by us with regular, expert inspection and maintenance – Always at competitive costs!

- YOU WILL NEVER NEED TO WORRY ABOUT MAINTENANCE WITH THIS MODULE.

- Minimum plant downtime.

- Transparent costs.

- Cost reduction through early fault detection and elimination.

SPARE PARTS & TOOLS MODULE

Tools, wear parts and consumables. We can give comprehensive advice on all of your needs, their technical suitability and their optimum use. By request we provide you with a monthly, quarterly or annual contract. Spare parts at competitive prices.

- WITH ORIGINAL KALTENBACH PARTS YOUR MACHINE LIVES LONGER.

- THE SPARE PARTS MODULE WILL ALSO SAVE YOU MONEY.

- Reliable and fast delivery.

- Guaranteed spare parts supply.

TRAINING & EDUCATION MODULE

Every machine is only as good as it’s operator. Regular refresher – Training and / or technology training for your operators and maintenance staff, will not only improve the productivity of your KALTENBACH machine, but also increases the professional qualifications of your employees.

- EXPERTISE AND BUILD YOUR KNOWLEDGE THROUGH THE TRAINING MODULE.

- Specially tailored to your needs and equipment.

- Increasing the life of the machine.

- Reducing errors, downtime and setup times.

- Ensuring consistent processing and product quality.

- Ensuring Factory Settings are maintained by highly trained maintenance personnel.

WHY BUY?

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

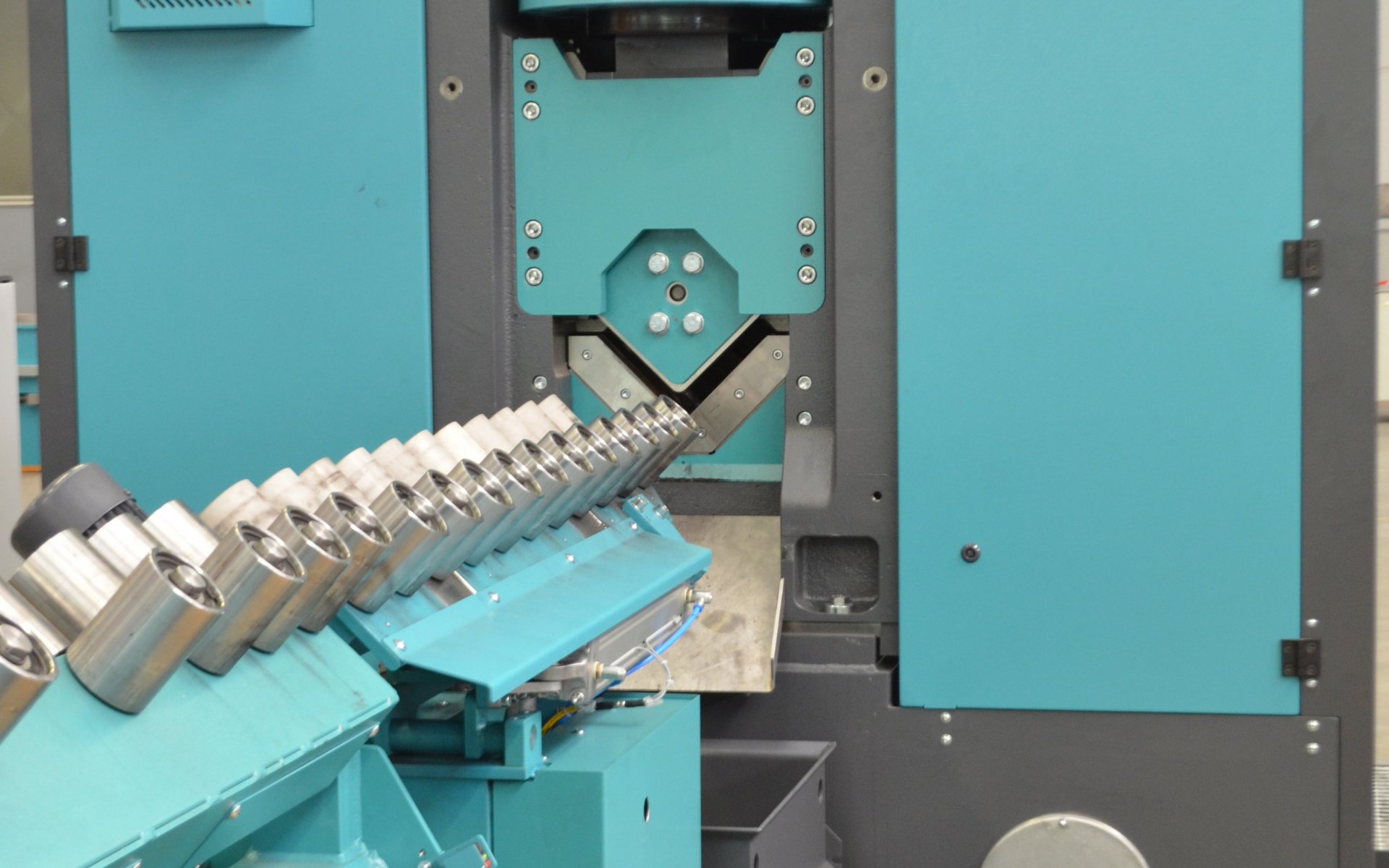

KALTENBACH KPSA 207 PUNCHING & SHEARING MACHINE

Powerful Punching-Shearing Machine for Angle Steel up to [mm] 200 x 200 x 25

The Kaltenbach Punching and Shearing System are based on our years of experience. It was completely redesigned and developed for low maintenance, speed and robustness requirements. The KPSA is suitable for punching and shearing angles and flat steel. Their robust and low-maintenance design and fast processes ensure maximum productivity.

BENEFITS AT A GLANCE

-

- High punching and shearing force

- Design is influenced by years of punching/shearing experience

- Sturdy construction for low vibration

- Compact machine design for space-saving installation

- User-friendly MULTILINE Software

- Low maintenance design with optimal access

- Quick tool change system minimal idle time

- Automatic die clearance setting for the highest quality shear

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from a Kaltenbach KPSA 207 Punching & Shearing Machine. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to deliver to your business and your clients successfully.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share the business challenges and solutions that you have encountered and how steel processing automation has helped achieve your business objectives.

JOIN HERE >>>