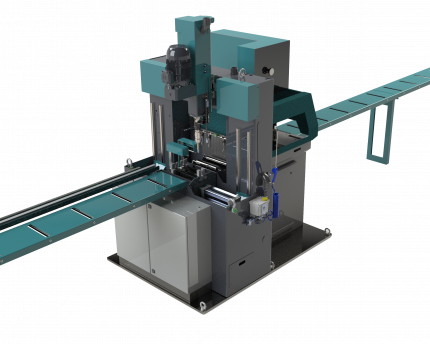

Kaltenbach KDU 250 Profile Drilling / Beamline Machine

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

FEATURES

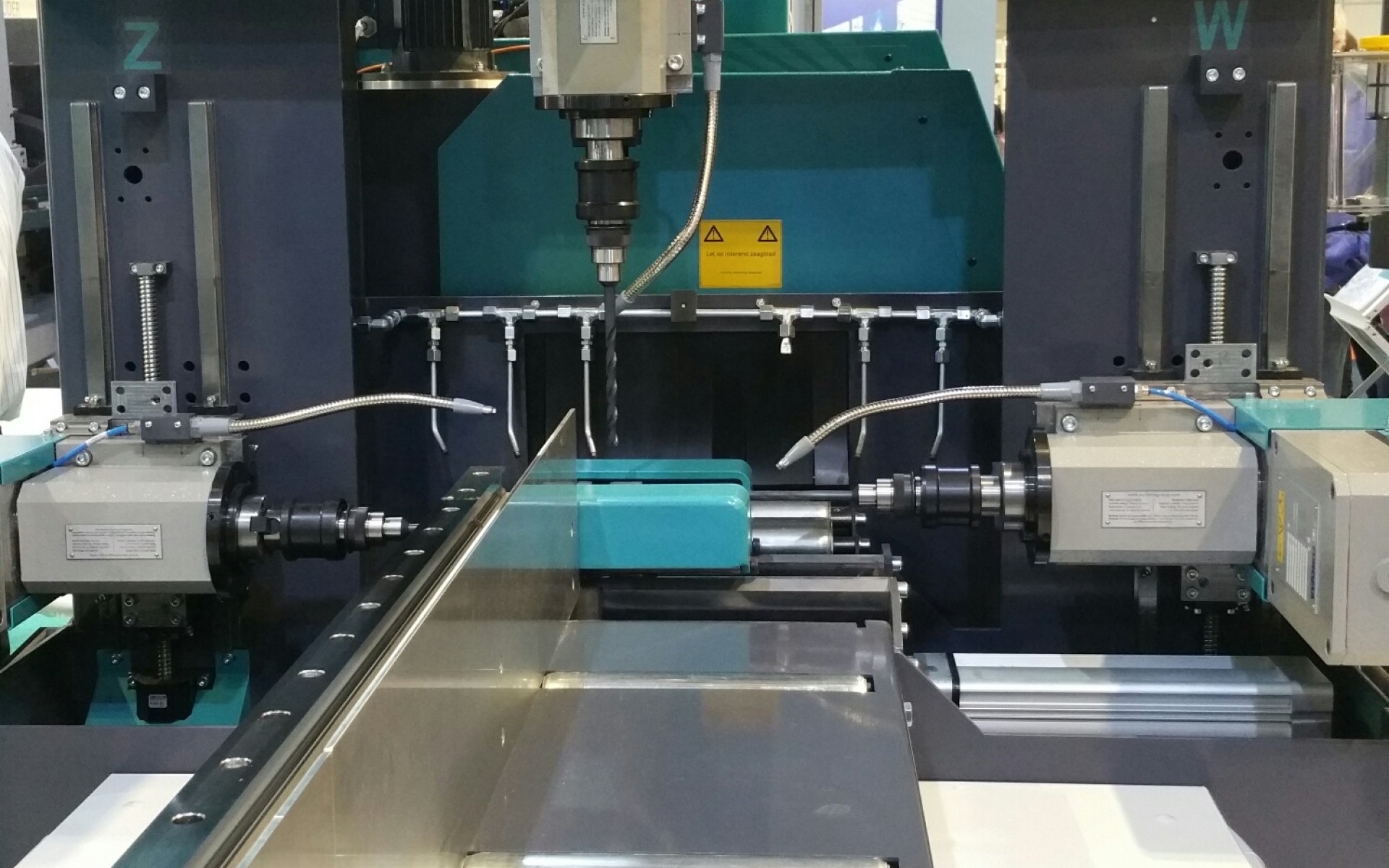

MACHINING DIVERSITY

- Efficient drilling, punching, countersinking and thread cutting on all drilling axes and optional saw cut

SPACE SAVING DESIGN

- Swarf tray mounted on rollers

- Optional swarf conveyor for automated, continuous swarf removal

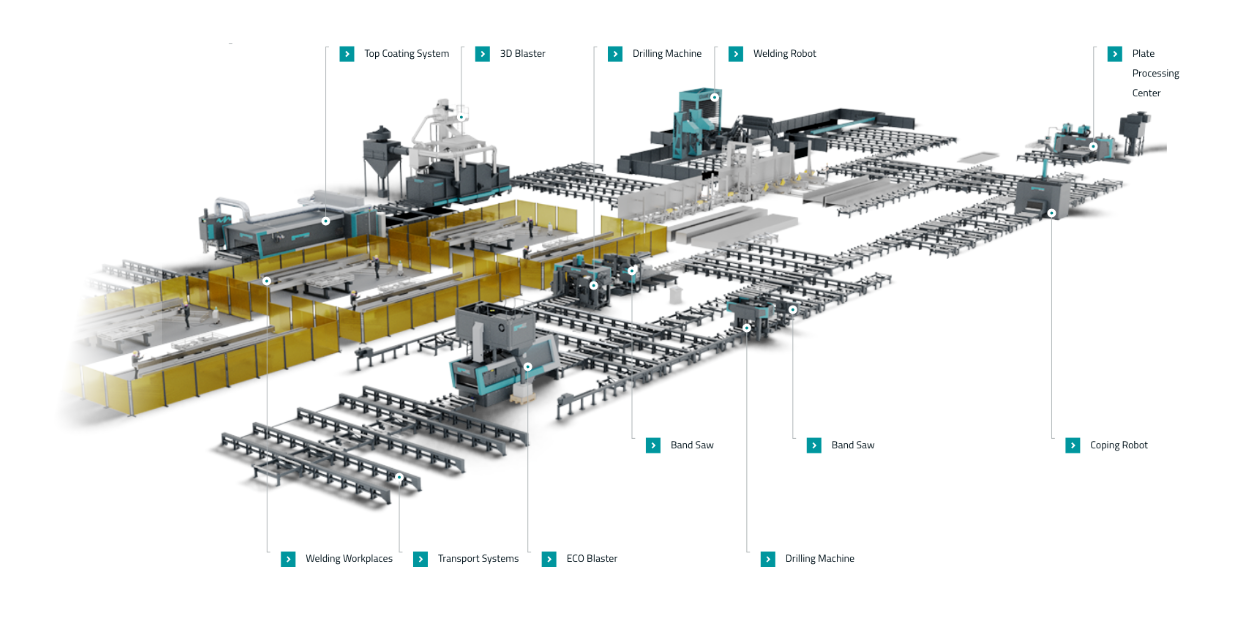

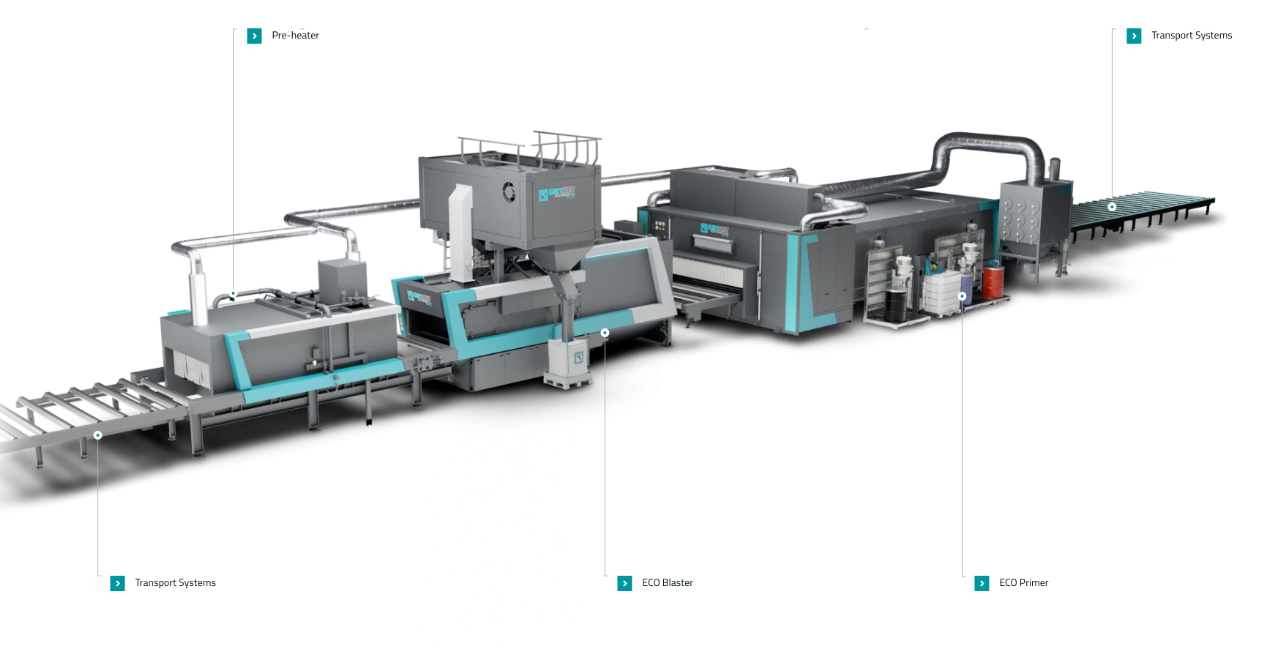

SAW-DRILL-LINE

- In combination with circular saw KKS or bandsaw KBS as automatic saw-drill-line

Simultaneous Handling from up to four sides

- Easy manual tool change at every drilling unit, optional tool changer

- Drilling possible from below

Low wear and low maintenance

- Drill carriage mounted on dual play-free, pre-stressed linear guide elements

- High precision during axis movement and when drilling

- Ball screw with a servomotor for high-precision positioning

.jpg?width=280&height=190&name=Tool%20changer%20(Option).jpg)

Tool changer (Option)

- 3 tools per axis

- MK3 tool holder

High Drilling Capacity

- Drilling feed via ballscrew spindle and servo motor

- Constant and repeatable feed rates

- Use of HSS tools

COMPLEMENTARY

KKS 450 U CIRCULAR SAWING MACHINE

- Universal sawing machine

- Clamping, sawing, reverse motion, opening – all at the touch of a button

- Robust and powerful transmission

KBS 400 DG BANDSAWING MACHINE

- Large cut and mitre area

- Easy to handle

- Precise saw cuts

SERVICE

HELPDESK MODULE

Whether by telephone, email or remote access, with the Helpdesk module you can take advantage of the expertise from our helpdesk team, for telephone advice and support. With remote access, we can fix (in 90% of cases) the problem quickly ensuring the highest possible system availability.

- Wide-ranging and professional fault diagnostics and solution.

- Shorter and less frequent service calls through targeted preparation.

- Individual advice and support.

MAINTENANCE MODULE

Minimize your downtime and achieve the best possible quality processing results from your KALTENBACH machine, always maintained by us with regular, expert inspection and maintenance – Always at competitive costs!

- YOU WILL NEVER NEED TO WORRY ABOUT MAINTENANCE WITH THIS MODULE.

- Minimum plant downtime.

- Transparent costs.

- Cost reduction through early fault detection and elimination.

SPARE PARTS & TOOLS MODULE

Tools, wear parts and consumables. We can give comprehensive advice on all of your needs, their technical suitability and their optimum use. By request we provide you with a monthly, quarterly or annual contract. Spare parts at competitive prices.

- WITH ORIGINAL KALTENBACH PARTS YOUR MACHINE LIVES LONGER.

- THE SPARE PARTS MODULE WILL ALSO SAVE YOU MONEY.

- Reliable and fast delivery.

- Guaranteed spare parts supply.

TRAINING & EDUCATION MODULE

Every machine is only as good as it’s operator. Regular refresher – Training and / or technology training for your operators and maintenance staff, will not only improve the productivity of your KALTENBACH machine, but also increases the professional qualifications of your employees.

- EXPERTISE AND BUILD YOUR KNOWLEDGE THROUGH THE TRAINING MODULE.

- Specially tailored to your needs and equipment.

- Increasing the life of the machine.

- Reducing errors, downtime and setup times.

- Ensuring consistent processing and product quality.

- Ensuring Factory Settings are maintained by highly trained maintenance personnel.

WHY BUY?

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

NEWS

- Dunsteel invests in Kaltenbach System

- If your fabrication workshop is not considering synchronising the shot-blasting and beamline together and working both machines in lights out automation perhaps you should be?

- Why is the steel service centre culture committed to investing in the cheapest beamline with limited capability, automation, speed or service reliability? No wonder value can not be provided to every profile competitively

- Why the fabricator needs to invest in a smarter machine than the steel service centre

- A fabricator should ask these questions before purchasing a beamline/coping robot to compare the workshop footprint ROI from loss of fabrication vs benefits of internal processing

- Ordering a beamline that works with NO LABOUR and in 100% automatic mode and lights out when everyone has left the factory

- Benefits for fabricating in house & reasons why to stop losing money purchasing processed steel from steel service centres that increase your fabrication man-hours by 40%, increase schedule & cost by 40%

- Any beamline manufacturer or agent of traditional beamlines or automatic systems must answer these critical questions to ensure the fabricator will be competitive

- Why the steel service centre refuses to include layout marking for add-on-parts AOP’s

- So what’s the problem with the steel service committing the cheapest beamline specification on the market?

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

KALTENBACH KDU 250 PROFILE DRILLING / BEAMLINE MACHINE

Drilling Machine for SMALLER Profiles

Workspace [mm]: 250 x 250

3-axis drilling machine for the automatic processing of smaller profiles. As well as drilling, the machine can also be used for thread-cutting and parts etching.

BENEFITS AT A GLANCE

-

- Robust, low-vibration design prolongs machine and tool life

- Machine portal in robust welded construction

- Drilling/centre-marking/counter-sinking/thread-cutting

- Powerful clamping system

- Rapid/working feed concept for shorter idle times

- Servomotor and ball screw

- can be incorporated to create a saw-drill combination

- Manual quick-change chuck

- Tool-centric processing minimises tool changes

- Use of HSS drills

- Up to four drill axes, each with one drilling tool

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from a Kaltenbach KDU 250 Profile Drilling / Beamline Machine. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to deliver to your business and your clients successfully.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share the business challenges and solutions that you have encountered and how steel processing automation has helped achieve your business objectives.

JOIN HERE >>>