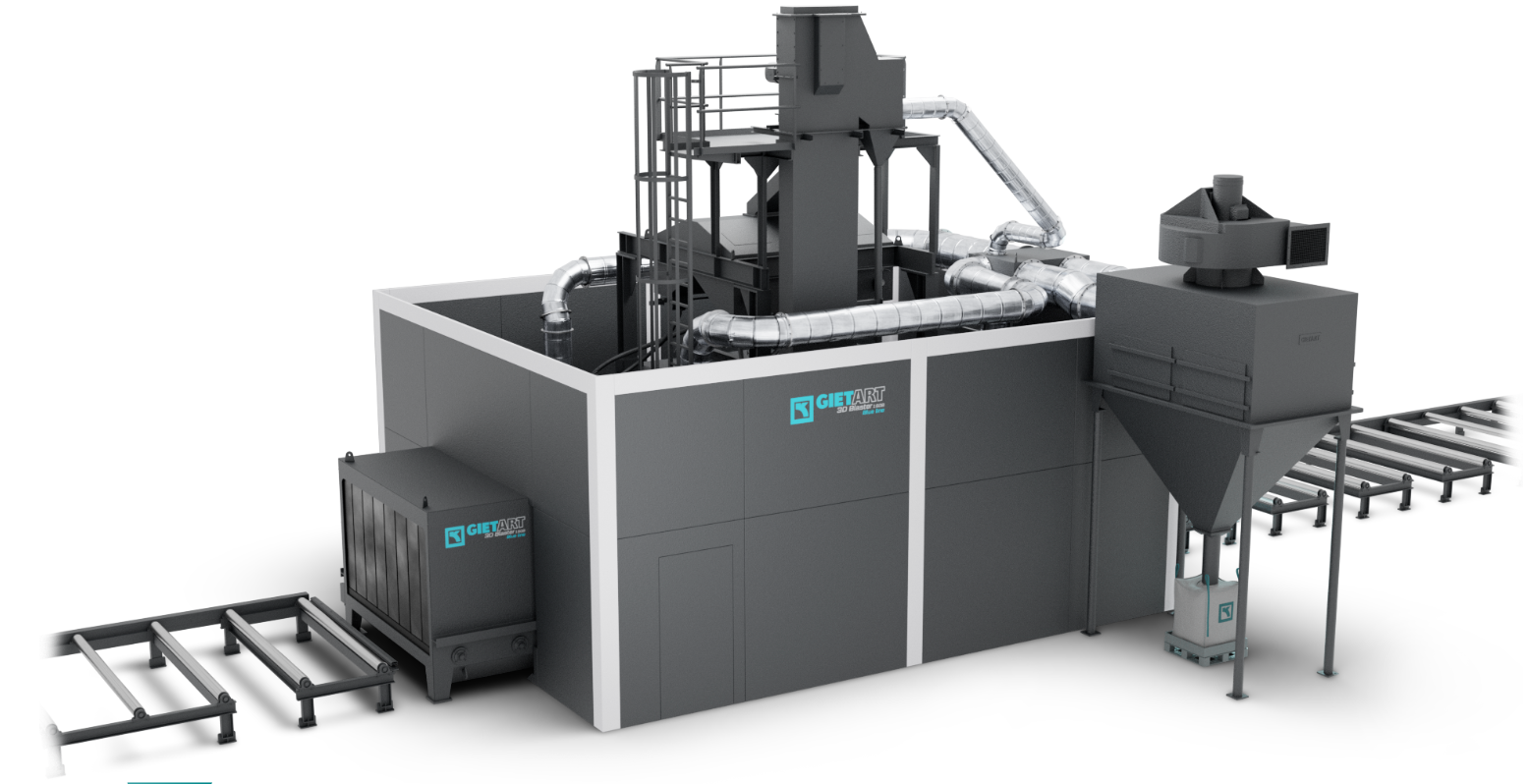

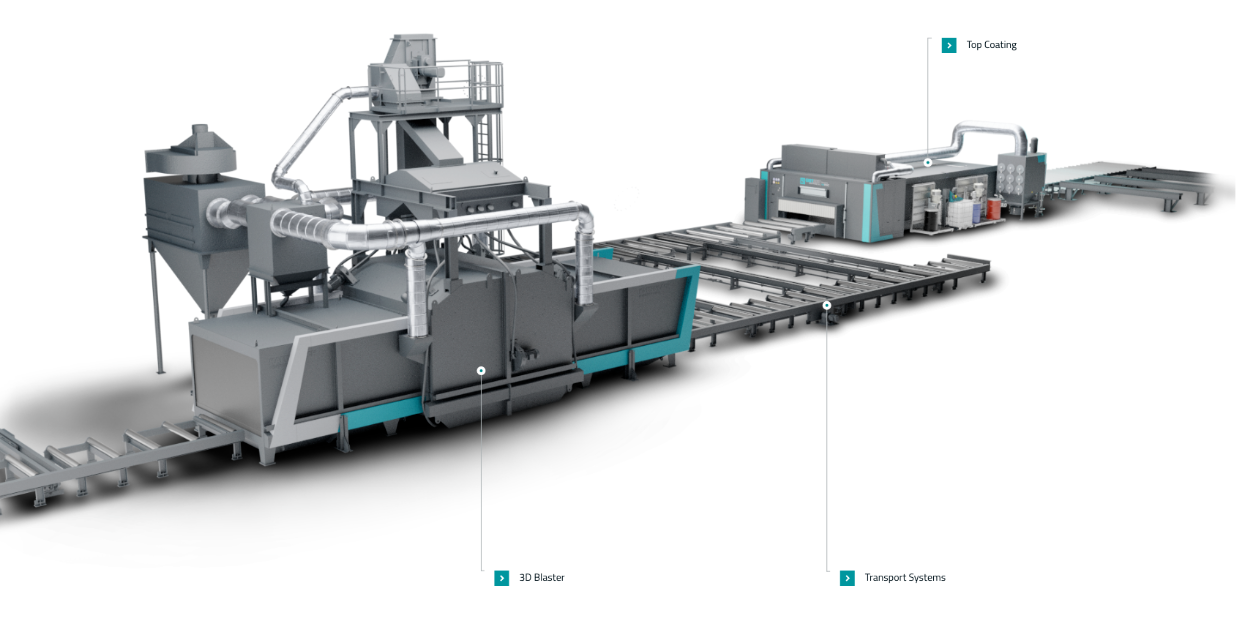

GIETART 3D Blaster 3010 Shotblast Machine

Some paragraph content...

WATCH THE VIDEOS

BROCHURES

- Gietart 3D Blaster Series

- Top Option Package - 7-Year Warranty

- Top Option Package - Blue Line

- Top Option Package - Industry 4.0

- Top Option Package - Tuned

- Top Option Package - Wear Resistant

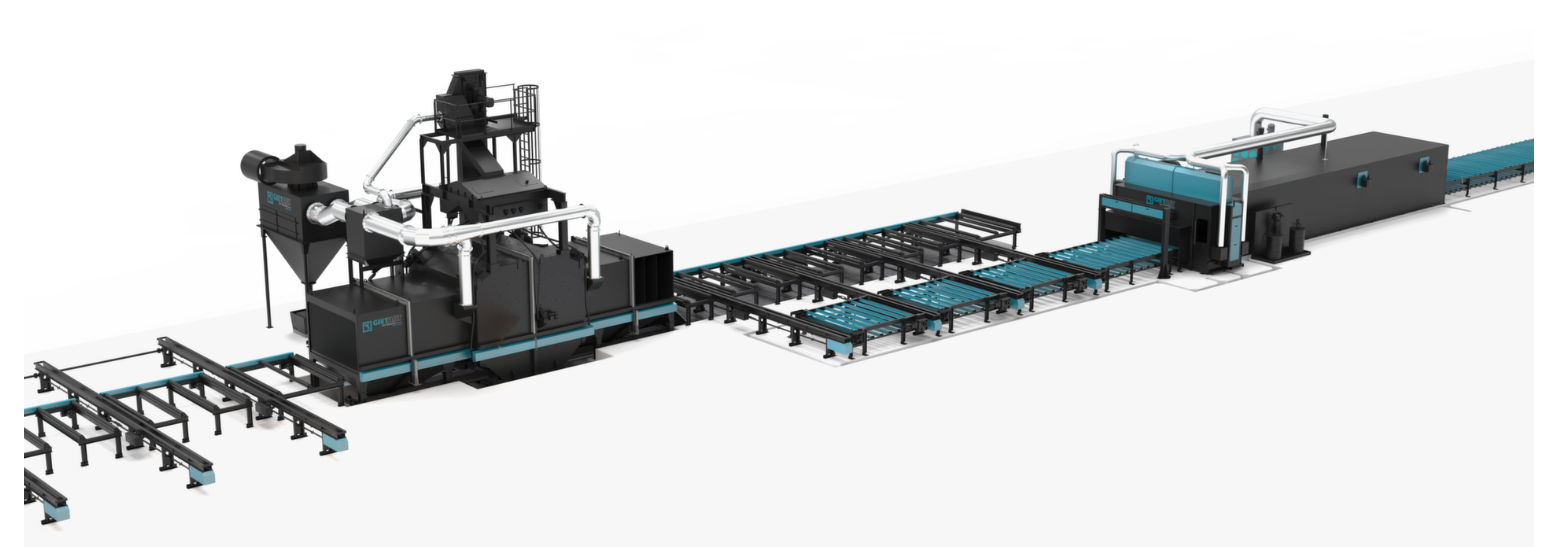

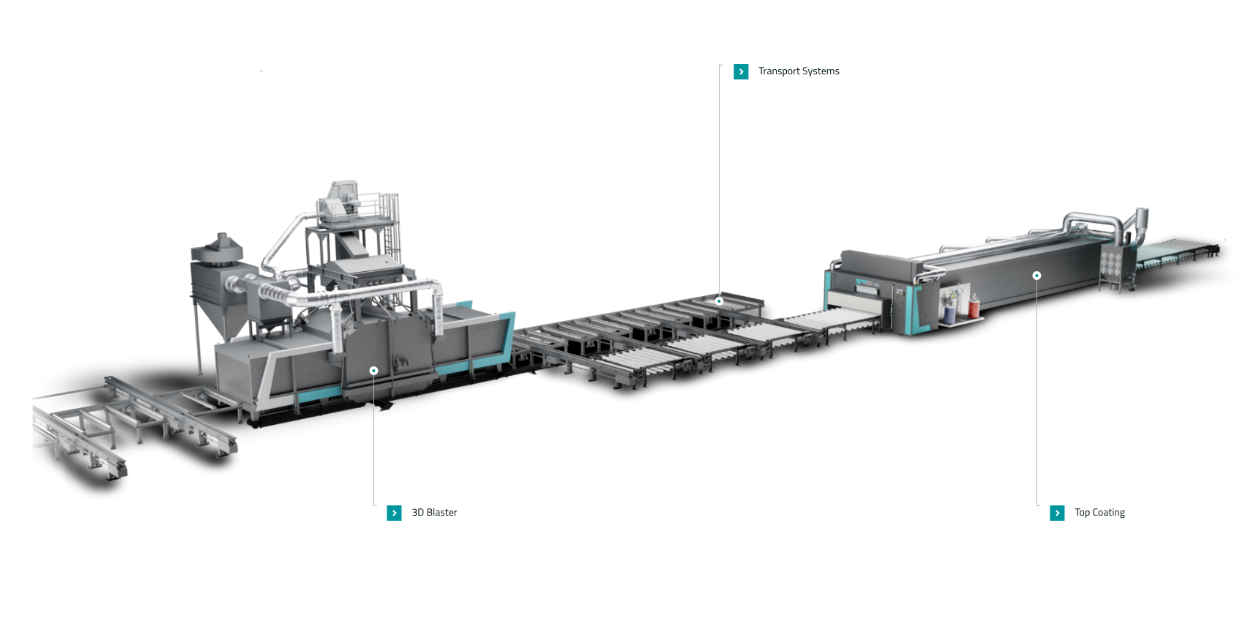

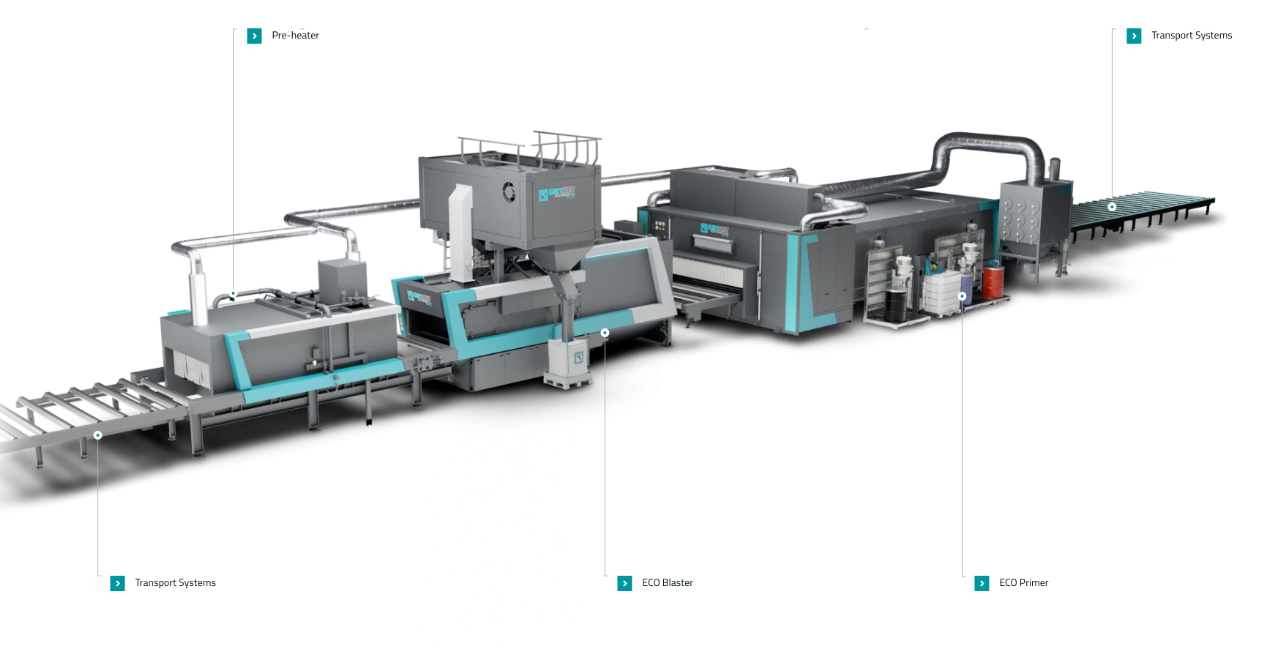

- Shotblasting and Painting – System Provider

- Systems for Service Treatment SST Product Catalogue

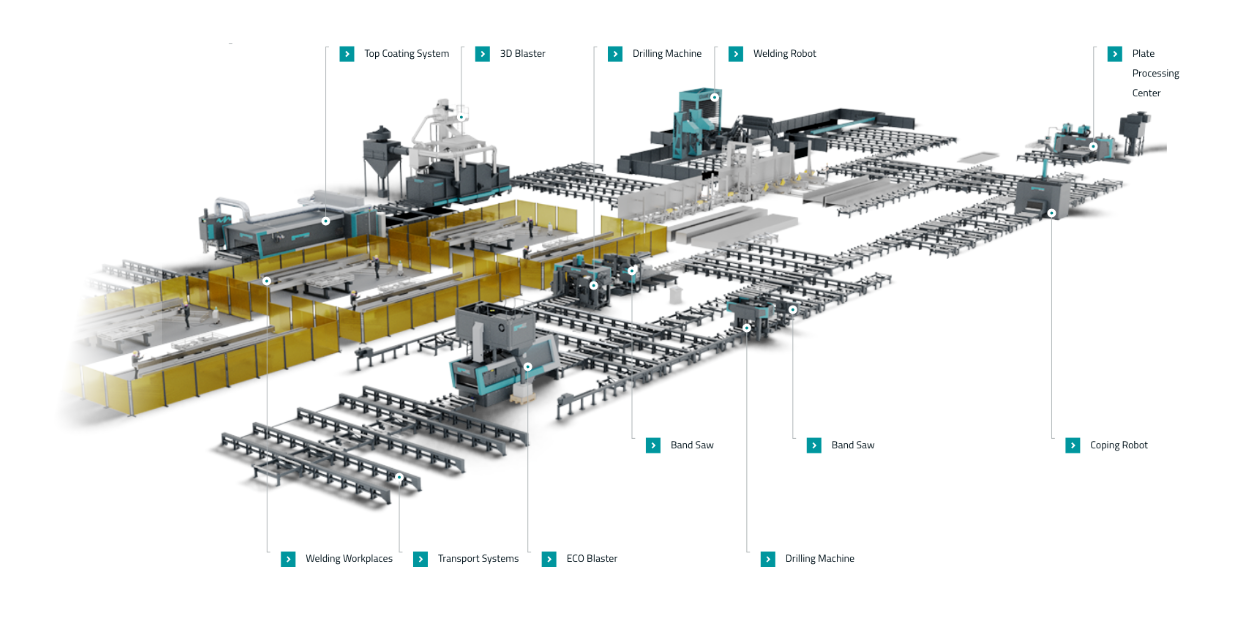

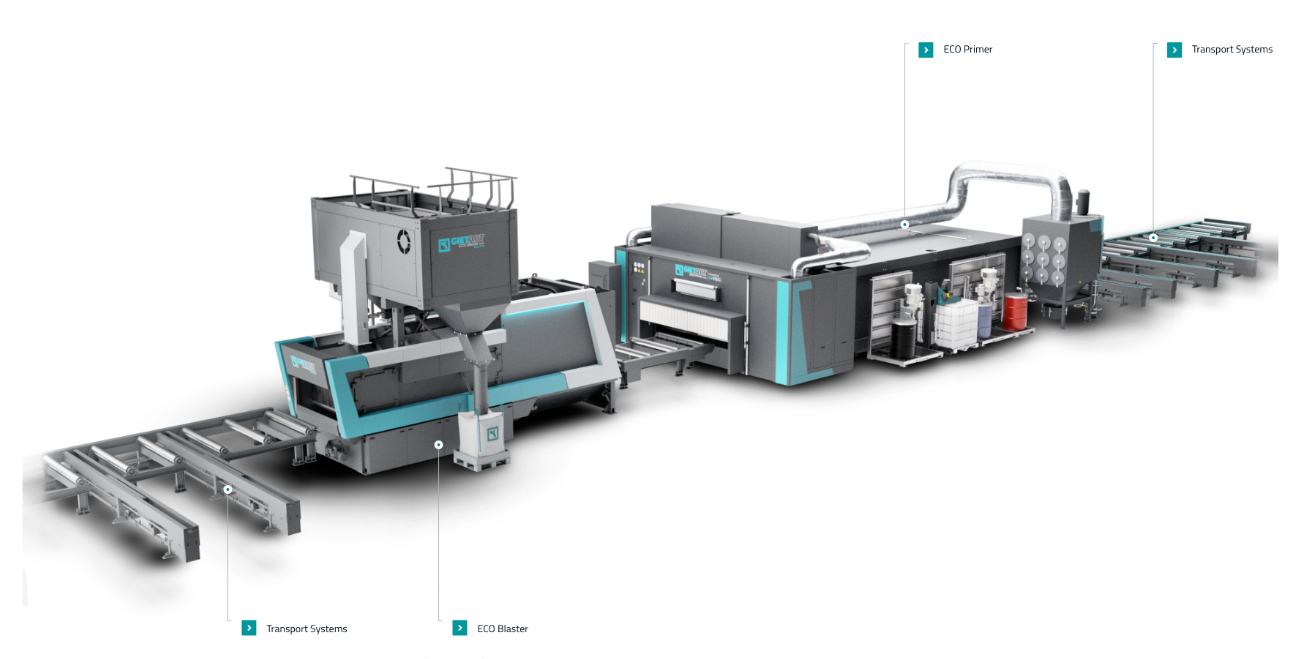

- Kaltenbach Sample Layouts

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

FEATURES

OPTIMAL SHOT BLASTING RESULTS

- Unique GIETART shot blast turbines, type C380, with 11kW or 15kW power

- Double disc turbine wheel with eight blades for optimum abrasive media use

- The turbine is directly driven by an electric motor with reinforced bearing

- Vertical mounting to the feedthrough direction. Thus optimum shotblasting results at the highest operating speeds.

- Good accessibility, easy maintenance

- Easy exchangeable blades and wearplates

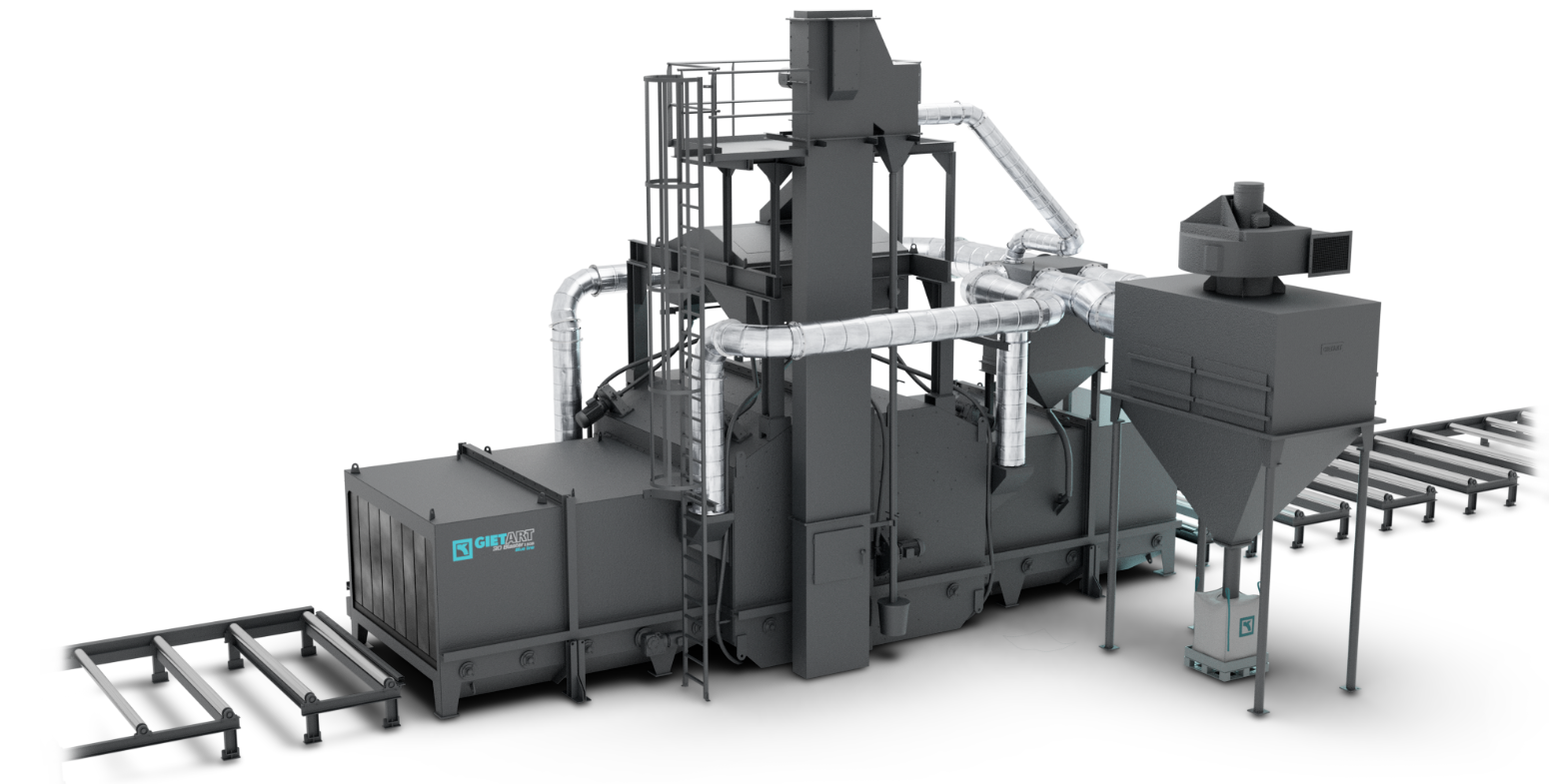

UNIQUE, DURABLE SHOT-BLASTING CONSTRUCTION

- In order to hold the abrasive inside the machine, the machine chamber is sealed - leakage of abrasive is limited and dust stays inside the machine.

- Inside the chamber, the rollers are made out of hardened solid material. Bearings are placed outside, protected by means of a labyrinth - lifetime of the bearings is considerably lengthened.

- In- and outfeed tunnel, if present, are closed by rubber curtains.

EFFICIENT AND EFFECTIVE REMOVAL AND REUSE OF ABRASIVE MATERIAL

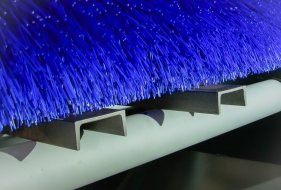

- By the use of the brush and blow-off system

- Abrasive media conveying system, brush and air-blowers are integrated into an adjustable supporting frame

- Precise adjustment to remove the abrasive media

- Easy control and changing of the brushes

EFFECTIVE REMOVAL OF DUST AND SCALE FROM ABRASIVE

- Optimum, multilevel cascade air cleaner removes dust and contaminations from the abrasive media

- Optimal blasting and cleaning results even with repeated use of the abrasive media

CLEAN WORKING ENVIRONMENT

- Purification of the vacuumed air (<1 mg / m2) by means of a cartridge filter

- Return of purified air to the work environment

- Long-life filter cartridges and thus low operating costs

- Easy accessible and exchangeable filter cartridges

EASY MAINTENANCE

- Optimal accessibility to the most important machine components for regular inspection and maintenance work

- Easy changing of the rubber curtains in the infeed and outlet tunnel

OPTIONS

SUITABLE FOR REMOVAL OF WATER AND FRESH POWDER SNOW

- Sustainable, high-end steel products

- Perfectly running process

- No dust clusters or rusted abrasives in the machine

- Increased uptime, as possible construction in hose will be avoided

- Conditions: Maximum water film 0.5 mm - snow and ice have to be removed by hand

SERVICE

HELPDESK MODULE

Whether by telephone, email or remote access, with the Helpdesk module you can take advantage of the expertise from our helpdesk team, for telephone advice and support. With remote access, we can fix (in 90% of cases) the problem quickly ensuring the highest possible system availability.

- Wide-ranging and professional fault diagnostics and solution.

- Shorter and less frequent service calls through targeted preparation.

- Individual advice and support.

MAINTENANCE MODULE

Minimize your downtime and achieve the best possible quality processing results from your KALTENBACH machine, always maintained by us with regular, expert inspection and maintenance – Always at competitive costs!

- YOU WILL NEVER NEED TO WORRY ABOUT MAINTENANCE WITH THIS MODULE.

- Minimum plant downtime.

- Transparent costs.

- Cost reduction through early fault detection and elimination.

SPARE PARTS & TOOLS MODULE

Tools, wear parts and consumables. We can give comprehensive advice on all of your needs, their technical suitability and their optimum use. By request we provide you with a monthly, quarterly or annual contract. Spare parts at competitive prices.

- WITH ORIGINAL KALTENBACH PARTS YOUR MACHINE LIVES LONGER.

- THE SPARE PARTS MODULE WILL ALSO SAVE YOU MONEY.

- Reliable and fast delivery.

- Guaranteed spare parts supply.

TRAINING & EDUCATION MODULE

Every machine is only as good as it’s operator. Regular refresher – Training and / or technology training for your operators and maintenance staff, will not only improve the productivity of your KALTENBACH machine, but also increases the professional qualifications of your employees.

- EXPERTISE AND BUILD YOUR KNOWLEDGE THROUGH THE TRAINING MODULE.

- Specially tailored to your needs and equipment.

- Increasing the life of the machine.

- Reducing errors, downtime and setup times.

- Ensuring consistent processing and product quality.

- Ensuring Factory Settings are maintained by highly trained maintenance personnel.

WHY BUY?

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

NEWS

- Prestigious American Good Design Award for IDPartners and Kaltenbach/Gietart

- Installation of a new GIETART SPRINT 1504 Shotblaster

- Dunsteel invests in Kaltenbach System

- If your fabrication workshop is not considering synchronising the shot-blasting and beamline together and working both machines in lights out automation perhaps you should be?

Request Video

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

gietart 3d blaster 3010 SHOTBLAST MACHINE

PERFECT FOR BLASTING WELDED STEEL CONSTRUCTIONS

Workspace [mm]: 3,000 x 1,600 and number of turbines: 10

BENEFITS AT A GLANCE

-

- Capacity depending on the shape and weight of the parts (substitute for TRIATHLON)

- Specially developed for welded steel constructions

- Perfectly cleaned end products

- Optimum recirculation of used abrasive

- Easy inspection and maintenance

- Option HD version: heavier turbines, higher impact, double speed

- Also available with significant energy saving option

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from a Gietart 3D Blaster 3010 Shotblast Machine. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to successfully deliver to your business and your clients.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share your business challenges and solutions that you have encountered and how steel processing automation had helped achieved your business objectives.

JOIN HERE >>>