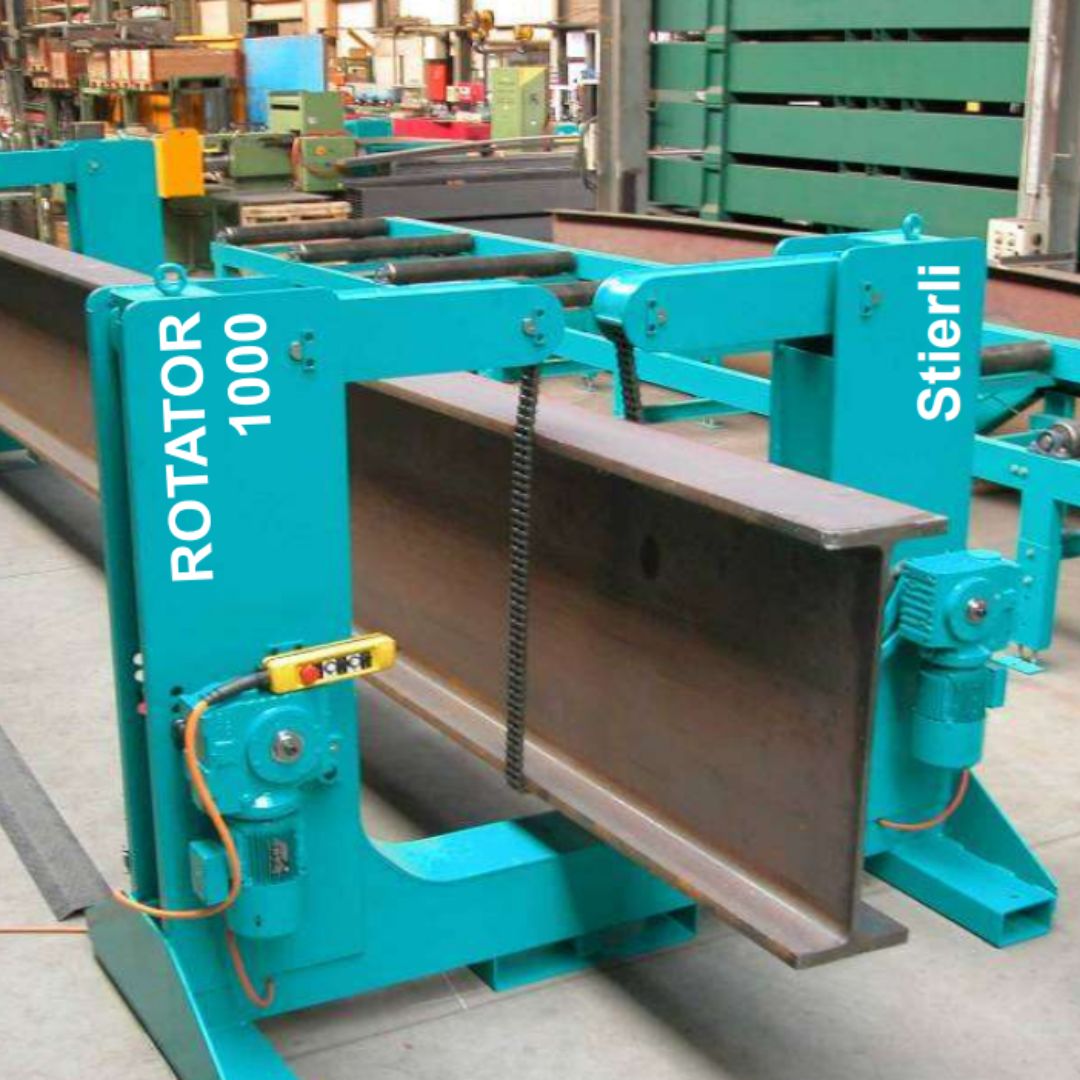

Stierli-Bieger Beam Rotator

Some paragraph content...

WATCH THE VIDEOS

HOW IT WORKS/BROCHURES

- Stierli-Bieger Beam Rotator – Presentation #1

- Stierli-Bieger Beam Rotator – Presentation #2

- Stierli-Bieger Main Brochure

- Stierli-Bieger Solutions for Steel Fabricators

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

WHY BUY?

- Clients of SMS using the Stierli-Bieger beam rotators are reporting receiving an ROI within 3 months if working two shifts or 6 months based on one shift

- The welder can have the profile at a comfortable operating & welding height to improve arc on efficiency over the complete shift and avoid becoming tired as the shift is ending.

- The profile can be rotated so the welder can be applying the weld at 45 degrees instead of 90 degrees

- Welders are reporting additional job satisfaction and self-esteem when they understand they have never been able to fabricate and weld so many profiles in a shift previously

- A significant and measurable increased tonnage and capacity per m2 of workshop space available without increasing headcount or putting on the 2nd shift

- The profiles can be rotated 360 degrees whilst in the rotator without using the overhead crane so the overhead crane can be used for other material handling activities. Welders are not waiting for overhead cranes that may be loading/unloading trucks or being used in other welding bays

- An improvement in man-hours required to fabricate and weld provides a competitive advantage to every project that deploys the beam rotators.

- The heat from the welding process can be efficiently spaced out over the profile that is easily rotated to avoid any rework on-site from heat-affected welded profiles

- 40-50% arc on efficiency improvement so the one welder using the beam rotator can increase capacity and improve schedules

- Fast turning for grinding and visual inspection

- Several rotators can be used in a line for very long parts to rotate efficiently and safely

- Efficient for testing the quality of the fabrication and fit-up prior to welding

- Any profile over 300mm is ideal for the beam rotator

- The rotators can easily be moved from the welding bay to the next with a forklift or overhead crane

- Safety and rotating of beams has improved largely fabricated profiles and limits soft tissue injuries when manually rotating profiles

- Ideal for rotating off-center profiles

- The older fabricator/welder is reluctant to 'give over' the beam rotator to the younger staff member as they have 'done their time' fabricating the hard way with traditional material handling methods

- Trusses, semi-trailer chassis and other large structures can be rotated safely and efficiently so a workshop can extend into other steel projects and hit schedules and improve the bottom line

- Additional man-hours are saved so the workshop can win more and do more

- When a workshop commissions the latest welding technology that is 30% faster than traditional MIG welding whilst also using the beam rotator this improves the profitability of the welding bays so the business can win more and do more.

- A fabricator will often start with the one container order of beam rotators and then order a 2nd container within 6 months so either 4-6 beam rotators are deployed within the workshop working 1-2 shifts per day.

- Steel Beam Assembly clients are using these beam rotators around the world as Stierli-Bieger is a recommended provider from us to their clients. The SBA will keep four welders busy per shift when using these beam rotators so a 2nd welding robot may not be required from the steel beam assembler

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

STIERLI-BIEGER BEAM ROTATOR MACHINE

Increase your productivity significantly – save over 30-40% of your working time.

The Stierli rotator was developed to turn heavy and large loads like beams and welded structures quickly and safely without a crane. This allows you to save a lot of working time and increase productivity. This welding positioner or welding manipulator functions as a lifting and rotating device with reliable chains.

The turning device is not only used for beam welding but other sections can also be turned with it, e.g. the use as a pipe turning device. Loading is impressively simple with the overhead crane or by pushing the rotator to the sides.

The rotator is also available with rollers. However, the smaller models can be positioned very easily with the hand pallet truck, whereby the distance between the stands of this welding device is freely selectable.

Explore an array of videos by clicking on WATCH THE VIDEOS above.

We will provide auditable, deliverable, measurable, and evidence-based metrics for your strategic team to calculate the ROI, capacity increase, and man-hours reduction achieved with a STIERLI-BIEGER Beam Rotator. SMS will assess your current position, ongoing strategy, and any gaps to ensure successful delivery to your business and clients.