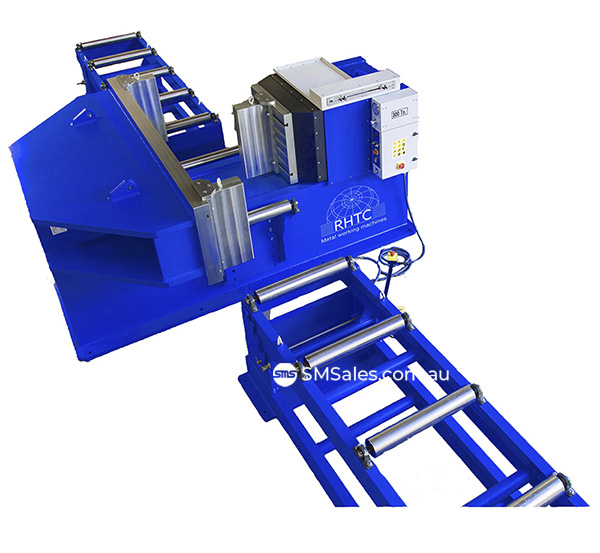

RHTC HV 150 - Beam Cambering Machine

Some paragraph content...

WATCH THE VIDEOS

TECHNICAL DATA

Profi-Press HV 150

150 tn

4 kw

300 mm

2 mm/sec

9.9 mm/sec

15.4 mm/sec

320 bar

450 mm

50 mm

700 mm

2000 x 500 mm

500 x 500 mm

100 x 100 x 500 mm

100 x 100 x 500 mm

900 mm

2520 mm

2000 mm

1570 mm

6700 kg

WHAT IT DOES

Q1: Why does a steel project require cambering? Is it for strength? Is it for architectural applications?

A1: Both, for cambering and straightening beams. They are often used in construction work, bridges, railways and in steel construction companies.

Q2: Why does any fabricator purchase these machines if they can order from the steel service centre?

A2: To invest in durability by cambering your own beams and to be dependent and flexible – over time it will save you money. The more camber jobs a company has, the better it is to buy a machine for it (instead of waiting in line at the steel service centre).

Q3: What skills or experience are required to operate a beam cambering machine?

A3: Not much, because with the standard cambering press, you set the stroke and push the pedal to make the pushing table go forward.

Q4: How do you prevent the beam from being 'over cambered'?

A4: By testing the stroke settings, step by step. You can set the stroke next to a lineal.

Q5: How many times would an operator have to push the profile through the machine for what would be considered a standard camber?

A5: Depends on the type of beam, but from a standard point of view, around 3 times.

Q6: Why is RHTC 40% more cost-effective than Swiss/Italian beam cambering machines?

A6: The Swiss Company is more expensive, even though they seem to use the same materials.

Q7: Would RHTC need to visit Australia for training/commissioning?

A7: Not necessary. Installation is super easy, and we provide an extensive manual in which everything is described step-by-step.

HOW IT WORKS / BROCHURES

The Profi Press cambering press is made in Europe and eminently suitable for straightening and bending large profiles and beams.

Key Features

- The control panel features a manometer, pressure regulator, a selector for manual or semi-automatic operation and a selector for the two different cylinder speeds (fast approach speed and slow working speed). With the end-stroke switches, you can easily regulate the cylinder stroke.

- The supporting back table and pushing the main table are equipped with T-grooves and support blocks. The main table ensures perfect alignment by means of four cylindrical lateral guides.

- A height-adjustable accompanying roller at both sides.

- Optional accessories. Basic supply rails with a length of 3.000 mm to 12.000 mm with height adjustment.

The electro-welded ‘C’-structure of our cambering presses is made out of ST-52.3 steel and these hydraulic presses are equipped with a supporting back table (made out of CK-42 stainless steel, with two ‘T’ DIN-650 grooves and with two support blocks) as well as a pushing main table (made of CK-42 stainless steel, with four cylindrical, lateral guides, two ‘T’ DIN-650 grooves and one support block).

The Profi Press cambering press is provided with a height-adjustable accompanying roller at both sides of the machine and equipped with a double-acting cylinder (including anti-turning) with a chrome plunger, stroke endings to regulate the cylinder stroke, a pressure regulator, gauge in tons and a two-speed motorized hydraulic unit with automatic disconnection of the high speed. The control panel of this straightening press features a selector for manual or (semi-)automatic operation and a selector for the two different cylinder speeds (fast approach speed and slower working speed). Operation is carried out by low voltage electric pedals.

The Profi Press cambering press is delivered with a warranty of 2 years and made with solely high-quality components for the best possible quality (fulfilling the latest CE regulations as well). These hydraulic cambering presses can be delivered with several options such as side benches with guide rollers, a larger piston stroke / vertical light, Siemens CNC-control or the geometry adapted to your needs to fulfil all your requirements for this type of press.

- RHTC Catalogue 2021

- Specialist Machinery Sales | Brochure

- Specialist Machinery Sales | The Art of Steel Processing Automation

- Specialist Machinery Sales | Client Testimonials

Click on the Why buy tab on this page to read the case studies that demonstrate good choices.

WHY BUY?

HOW TO BUY?

- Intro) Advice Made of Steel – Handshake & Hello

- Step 1) Steel Processing Innovation

- Step 2) Working Together – Market Position

- Step 3) Working Together – PEST Analysis

- Step 4) Selection of Equipment & Selection of Solution

- Step 5) SWOT Analysis

- Step 6) Automation Design Lifecycle Planning

- Step 7) Business Process Brief

- Step 8) Balanced Scorecard

- Step 9) Confidentiality Agreement

- Step 10) Flexibility Study Part 1

- Step 11) Flexibility Study Part 2

- Step 12) Flexibility Study Part 3

- Step 13) Flexibility Study Part 4

- Step 14) Flexibility Study Part 5

Request Machine Demo

Request Software Demo

Request Layout

Request Visit

Request Quote

RHTC – HV 150 – BEAM CAMBERING MACHINE

RHTC's cambering presses are specially designed to carry out the straightening and bending of profiles, bars and beams. The horizontal design of this cambering machine permits the easy handling of large beams and profiles. This 150-ton cambering press is the ‘smallest’ model for straightening and bending profiles, bars and beams that RHTC can deliver. This standard HV-150 press has a piston stroke of 450 mm (which can be regulated by means of stroke endings) and the maximum opening between the supporting back table and pushing the main table is 700 mm.

All RHTC straightening presses meet and satisfy the essential health and safety requirements in accordance with the latest CE standards and are delivered with a warranty of 2 years. Furthermore, these hydraulic cambering presses can be adapted to special needs such as a larger vertical light or faster speeds, please contact us for more information.

Note: Models with bigger dimensions / tonnages (up to 800 ton) are available on request (these are not standard).

Auditable, deliverable, measurable and evidence-based metrics will be provided so your strategic team can calculate the ROI, capacity increase and man-hours reduced from an RHTC HV 150 Beam Cambering Machine. SMS will evaluate your current position and ongoing strategy, we will then assess any gaps to successfully deliver to your business and your clients.

JOIN OUR LINKEDIN GROUP

Join our growing and exclusive LinkedIn Group - Innovating Structural Steel Processing and Fabrication Group. In this group, we bring in thought leadership content, topics, trends and challenges within the steel industry and steel processing automation. We encourage everyone to share your business challenges and solutions that you have encountered and how steel processing automation had helped achieved your business objectives.

JOIN HERE >>>